Introduction

Silk screening or screen printing involves transferring ink on a surface with the help of the screen stencil. It gives vivid and multi-colored designs and very long-lasting prints. Screen printing has gained popularity among most apparel enterprises due to its ability to produce vivid images which are durably washable. Simply put, this is the method through which logos, and arts are printed onto the T-shirts, hoodies, and other clothing items, and signs and posters. So the question is can you screen print on polyester?

In contrast, polyester is a man made material that is appreciated because of its strength, moisture wicking capability and great color retention. It can be found frequently on sports apparel, sports clothes and outdoor equipment. Nevertheless, ink does not stick easily on polyester smooth non absorbent fibers and the material can easily be heat sensitive. Its dyes can even bleed (migrate) in strong curing temperatures. All these imply that there are specific challenges of screen printing on polyester. Is it possible to screen print on polyester? This is a question that we will discuss thoroughly and come up with tips, tricks, and best inks to use.

Can You Screen Print on Polyester?

Yes – you can screen print on polyester, however screening polyester needs some modification. The properties of Polyester are dissimilar to those of cotton which easily absorbs ink. Fibers of polyester are artificial, smooth and cannot absorb the ink similar to cotton. This means that normal inks can fail to adhere especially without additional agents. Actually, in practice, manufacturers of plastisol or water-based inks suitable to synthetics are used by printers, who may add migration-blocking or adhesion-enhancing additives. Polyester is also cured by lower temperatures so as to prevent dye bleed by printers. Even with such modifications, polyester clothes will still give a good and strong screen print.

Challenges of Screen Printing on Polyester

Printing on polyester is a unique hurdle that other natural fibers such as cotton lack. Synthetic and slippery fibers in the fabric imply that it is necessary to consider the issues in adhesion of the ink, migration of dyes as well as distortion. The inability to adjust to such factors may lead to print defect or color variation. We discuss the key issues with applying ink, ink adhesion problems, a risk of dye migration, and fabric distortion in the sections below to assist you in avoiding those.

Ink Adhesion Issues

Fibers made of polyester are slippery and unabsorbent, which makes the ink challenge to hold on to the fabric. An average plastisol print used on polyester can peel off or bead up when not able to penetrate through the fibers. Also, polyester garments (including the majority of them) are finished (such as stain- or moisture-resistant treatments) and the ink will not stick to them. Against this printers take special precautions: they add adhesion-promoting powders (e.g. Poly-All) to the ink or choose synthetics-specific inks. Such additives form a chemical bond making the ink stick better to the polyester fibers, thus decreasing peeling and cracking.

Dye Migration Risk

The other key problem is the dye migration (bleeding). During curing polyester dyes may sublimate or bleed into ink. As an example, printing with white ink on red polyester may leave the print pink or gray in the matter of days due to curing. This occurs primarily at elevated temperatures (greater than about 300 o F) or when delicately died textiles are used. Printers employ low-bleed plastisol inks and special underbases, with blockers to dye, in order to inhibit migration. As an example, ICC Guardian Gray (a plastisol underbase) is intended to prevent dye travel on polyester. Also, printers cure at lower temperatures (285300 3 F) and, in general, will use conveyor dryers (non-contact curing) so that very little bleeding occurs. The process is used to fix the color in the garment dye and maintain the print color.

Fabric Stretching & Distortion

Polyester clothes have the ability to bend and lose shape particularly when elastic fibers such as spandex have been used. When the material is stretched on the press the design can twist and crack because the fabric is allowed to relax. To prevent this, the printers operate on un-stretched fabric and flatten the garment beneath the screen. Application of high screen tension and low off-contact gap also helps since it minimizes any tendency of the fabric to move. When using very stretchy types of poly blends, there are options of using what is called sat stretch inks which have built in elasticity to allow the print to move in conjunction with the garment. This can also be guaranteed by proper curing and cooling on a flat surface to make sure that the design is not deformed after completion.

Best Inks for Screen Printing on Polyester

Choosing the right ink is critical for screen printing on polyester. Not all inks bond well to synthetic fabrics. Here are the ink types that work best on polyester:

Plastisol Ink (Standard PVC Ink)

The screen printing industry workhorse is plastisol. In plastisol inks, on polyester you will find out that you need to use low-bleed or poly-formula plastisol ink. These inks do not need a high temperature to cure and include migration inhibitor to block passage of the garment dyes through. Practically the printer can print color on dark polyester allowing a very low-bleed white underbase to be laid first. Plastisol prints lie on top of the fabric and provide very good opacity and bright colours, but provide a heavier hand feel. In general, poly-specific plastisols (which can also be referred to as polysol inks) are suggested using applications that require vividness and durability in print on polyester.

Water-Based Ink (with Binder)

To obtain a soft print, on polyester, it is possible to produce a water-based ink (particularly acidified) that has been modified to suit synthetics. These inks are absorbed into the fabric as opposed to being on top of the material making it feel more breezy. Raw water-based inks are however fast drying, low density on polyester and are often supplemented with either binders or thickeners to enhance adhesion and coverage. Environmentally friendly water-based combinations might be more technical to have a clean print on polyester, but produce extremely soft, flexy prints once correctly executed.

Discharge Ink

The dye that is already on your shirt is taken away using a discharge ink and allows your ink color to come to the surface. Discharge may produce an extremely soft, natural print on lightly coloured polyester-blend fabric. But discharge only acts on natural fibres-100 per cent polyester will not discharge its colour. Concisely, pure polyester has no favourable susceptibility towards discharge ink. It works well with a shirt containing cotton or being light-colored, not with the pure ones manufactured of polyester.

Nylon Ink

Special plastisol are put together in nylon-specific inks that are made along with synthetic fabrics. In many cases they incorporate catalysts or additives, which increase adhesion to slippery surfaces. Such as a nylon ink (or plastisol/addition of an adhesion promoter) can be bonded effectively to a polyester mix or technical fabric. These inks show how injection inks can be designed to overcome adhesion issues. Pure polyester tend to only require low-bleed plastisol although in the synthetics arsenal a printer has, there is also the nylon ink.

Pre-Treatment & Fixing Agents

Polyester shirts usually require special treatment to have ink stick and remain vivid. Printers can use a chemical coating or primers which will adhere to the fibers. The addition of adhesion promoting additives and polyester-blocking underbases are the two common methods. The two techniques aid in circumventing the resistance of polyester and avoid incidence of dye bleed.

Adhesion Promoters

The adhesion promoters are the chemicals that enhance adhesion of ink to adverse fabrics. In the case of polyester, a typical approach consists of adding some of an adhesion-promoting powder to the ink. As an illustration, Nazdar made its plastisol tacky by using its additive called, Poly-All in order to enable the ink adhere perfectly to polyester. Other printers even spray a primer on to the garment. Such processes make the ink more inseparable to the manmade fibers, thereby avoiding peeling or cracking during usage.

Polyester Pretreatments

Pre-treatments of polyester often consist in printing, or coating with a blocking layer. The most commonly known of this is ICC Guardian Gray 7043, a plastisol underbase meant to prevent dye migration on polyester. The printer deposits this blocker in thin lay- down and fully cures it and adds the actual design inks. Other treatments can be applied by spraying polyester (and other) treatment such as silicate-based type treatments or polyurethane treatments that retains the dyes in place. Overall, the pretreatments of polyester in essence form a bleed-resistant coat to ensure the end print holds form.

Step-by-Step Guide to Screen Print on Polyester

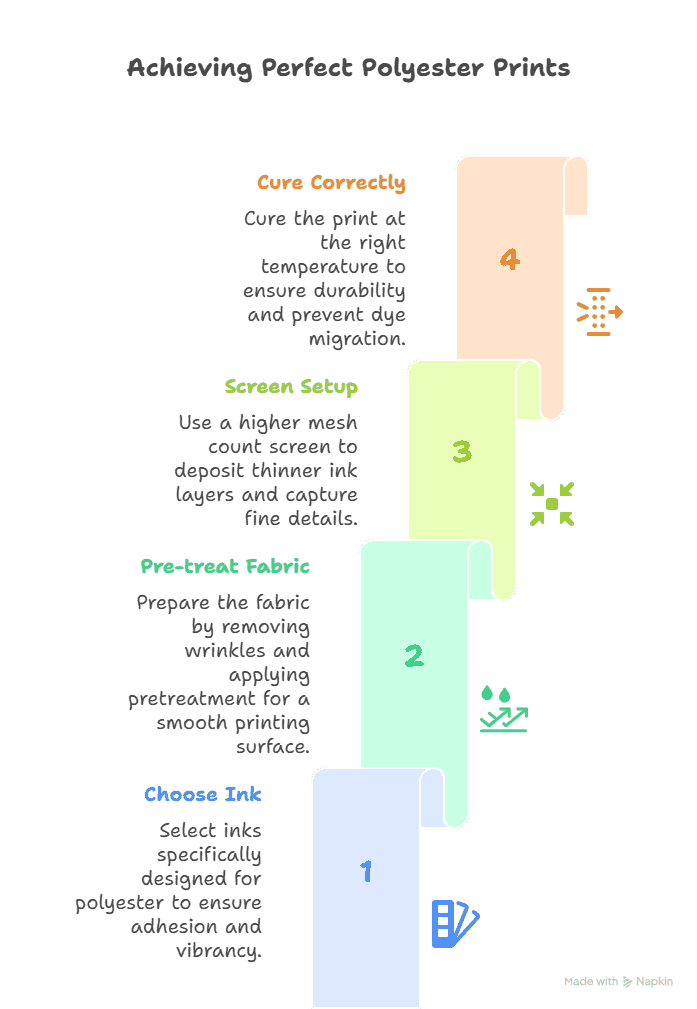

1Step: Choose the Right Ink:

- Start always with the choosing of inks which are made to work on polyester. A low bleed plastisol identified as synthetics is normally preferable. Alternatively, apply a kind of high quality water based ink and a special binder on the synthetic fabrics. Do not use normal discharge ink on 100 percent polyester as that is out of the question. To be brief, choose a type of ink, which has been prepared to work on polyester blends so that it can stick and remain lively.

2Step: Pre-treat the Fabric:

- Hoist the garment to get rid of wrinkles and lint. In case you wish to use an adhesion spray or sticky pretreatment, put it on now so the shirt can remain flat under the screen. And also any barrier or blocker underbase is first printed. As in the case of an example, you could use a thin plastisol under base color called Guardian Gray and flash-cure the under base before color layers. The dyes are put on lock down by this pretreatment agent and it provides a smooth surface on which the design is printed.

3Step: Use Proper Screen Setup:

- Use a higher mesh count (like 156–230) for polyester to deposit thinner ink layers and capture fine detail. Higher tension and minimal off-contact help, as they reduce ink penetration and fabric movement. If printing a white underbase, you might use a slightly lower mesh (e.g. 156–200) for better opacity, but always minimize excess ink. Thinner ink films reduce the chance of migration and create a cleaner print.

4Step: Cure Correctly:

- Curing is crucial for polyester. Aim for a cure temperature in the range of about 280–300°F (138–149°C). A conveyor dryer is ideal (non-contact curing) to avoid overheating parts of the print. If using a heat press, try a ‘hover’ or low-pressure method with the lowest effective temperature. Test that the ink is fully cured (it should not rub off). Proper curing will make the print durable while minimizing dye migration or scorching the fabric.

Curing & Drying Polyester Prints

Ideal Temperature and Time

The temps at which polyester prints are cured are lower than cotton. Preheat to approximately 265 to 300 o F (140 o C to 149 o C). In practice, several printers are aiming at 285F or below to avoid dye bleed. Depending on the equipment, it takes a certain amount of time (this is typically 15-30 seconds). The temperature of garment should always be monitored, over 285 degrees F may even disintegrate a garment and some standards have suggested to maintain it about that level. This may result in overheating of the dye and in cases where the fabric is likely to melt, a thermometer strip or probe should be used to confirm the cure.

Using a Heat Press vs Conveyor Dryer

The best technique to use in polyester is a conveyor dryer. It allows stable indirect heat as well as prevents hot spots. This again can be compared with the suggestion of Lawson who proposes that a tunnel conveyor is used, and that the shade temperature of the shirt be kept below 285 F. In case only heat press is available, lower the temperature (use 280300 F) and the shortest time possible. They can be applied by the so called hover method (no pressure) and then the ink can be smoothed by a finger. In any instance make sure the ink has cured completely; it ought not to be seen to transfer on to a test tissue and finally inspect that the cloth has not been torn.

Common Mistakes & How to Avoid Them

Even experienced printers can run into trouble with polyester. Here are common errors while screen print on polyester and how to fix them:

Overheating

One of the biggest mistakes is overheating. Putting polyester prints in too hot or for too long can reactivate the fabric’s dyes, causing ghosting or discoloration. It can even scorch or shrink the fibers. To avoid this, keep cure temperatures in check (around 285°F or lower). Always monitor the dryer and reduce heat if you notice any color shift (for example, a white print turning pink).

Wrong Ink Selection

Using the wrong ink will ruin the print. If you use cotton-only inks or try to discharge 100% polyester, the design will fail. Polyester needs inks formulated for synthetics. Using a rigid or low-flexibility ink will lead to cracking when the shirt is worn. Always verify that the ink label says it works on polyester blends. Testing an ink on a scrap of the same fabric can prevent costly errors.

Poor Curing

Poor curing is a problem too. Inadequately cured ink can be washed off or be sticky and excessive curing can cause dye migration or destruction of the fabric. Ink and equipment should be at the proper time and temperature. Wash a test print: when the image washes or cracks, change what you cure. Overall cure on the side of under curing and retest rather than modifying risk melt. It is durable when it is cured properly.

Alternative Screen Print Methods for Polyester

Polyester may not be decorated using screen printing only. Other procedures are:

Direct-to-Garment (DTG) Printing:

This is ink jet printer used to print on a garment. It usually uses cotton but polyester may be printed with DTG as long as it is done with a special pretreatment. In DTG, the shirt is sprayed by a pre treatment solution which allows the ink to adhere and then the design is printed. The garment is then cured (usually with a conveyor dryer between 265 and 285 o F) to set the ink. DTG is able to print photographic full color prints without difficulties. Nevertheless, it is expensive and needs a critical pretreatment.

Sublimation Printing:

Dye sublimation is a good process on 100 % polyester material. In this case, the design is printed on special paper (through sublimation inks). The design is then pressed into shape with a heat press that causes the ink to become a gas and permanently saturate the polyester fibers. The outcome is very dynamic, eternal prints which lack additional hand or thickness. It is a weakness that sublimation can only be applied on white or light-colored polyester (the design is transferred in form of dye and not ink). However, on appropriate clothing, it is great in terms of quality and wash ability.

Heat Transfer Vinyl (HTV):

In heat transfer vinyl, a verge is obliterated in a sheet of vinyl using a cutter and the design is then unwary-pressed on the fabric. Its use is so as many HTVs are designed to stick to polyester at lower temperature. HTV is ideal on plain text logos or lettering and is also popular where small runs or one off work is involved. It gives a clean solid finish, but the vinyl feels a wee bit thicker as compared to printed ink. In case of polyester, apply manufacturer-recommended, low-temp and use only thin cover sheet in order to prevent scorching. Less popular with complicated designs, HTV is highly amicable with novices.

Conclusion

Polyester can definitely be screen printed, though care is needed and the proper materials used. To conclude, low-bleed inks, control cure temperature and think about pretreatments to block dye. Try all new ink and fabric combinations to calibrate your process–rarely can you get away with big changes in ink mix, mesh or cure. In the case of 100 percent polyester and high performance sportswear, the best choice is low-cure plastisol or appropriate water based inks.

In case of necessity, dye sublimation is really the best case to be used when it comes to all-poly garments; meanwhile, DTG or HTV should be employed in case of short-runs or more intricate designs. And most important: before a full production run, do a test print: on no account should you have a production run and find out afterwards, after washing, that your prints will turn out still and yellow, or will crack, or become dishonest. Although care must be taken in testing, these suggestions when adhered to will give brilliant and lasting printings on polyester fabrics. So hope your question, “Can you screen print on polyester?” has been solved.

FAQs

Yes, with the right ink and curing temperature. Use low-bleed plastisol or synthetic-safe ink to prevent dye migration.

Cracking usually results from poor ink adhesion or incorrect curing. Use polyester-specific inks and make sure to cure at the correct temperature.

Use low-bleed plastisol or nylon inks with a bleed-blocker underbase. These inks prevent dye migration and maintain opacity on dark fabrics.