Introduction-

Consider that great fleece jacket in your wardrobe you want on a brisk evening or the cozy blanket on a cold night. The comfort has the feel of natural wool. But the reality is shocking– polar fleece is not a natural fabric to be found. It is rather the product of present-day science and recycling technology.

Although similar in its ability to keep you warm, polar fleece is made of man made fibers, mostly polyester, and often is sourced to the recycled plastic bottles. This makes it stand among the greatest inventions in the textile industry.

This article is going to touch on what polar fleece fabric is, how it is manufactured, its features, advantages and disadvantages, various types and varieties, comparisons, care regulations and environmental effects. By the end you will see how plastic can become a fluffy comfort and why this fabric has been so popular in our day.

What Is Polar Fleece Fabric Made Of?

At the root of it all, polar fleece is 100 percent polyester, also referred to as Polyethylene Terephthalate (PET). The secret to magic is its sources. Contrasting wool which is obtained through the long process of grooming and shearing sheep, polyester is a man-made fiber that is made using petroleum-based chemicals or recycled plastics.

Source Material: From Bottles to Fibers

Recycled plastic bottles have become the most popular raw material of polar fleece nowadays. Collected bottles that have been used are gathered by manufacturers, cleaned, shredded into a flake, and then melted into pellets. These pellets then are extruded to form fine polyester fiber. This recycling initiative is not only environmentally friendly, but also less space consuming and it manufactures a soft, durable material.

A Brief History

Invented in 1979 by Malden Mills now named Polartec Polar fleece was the first wet weather fabric used by hikers trekking in the mountains. It was created as a synthetically made replacement to wool, but it is lighter. Such was the success of the innovation that it scooped awards and became an instant fabric in everything outdoor. Since that, fleece has been the synonym to the words of warmth, affordability and sustainability.

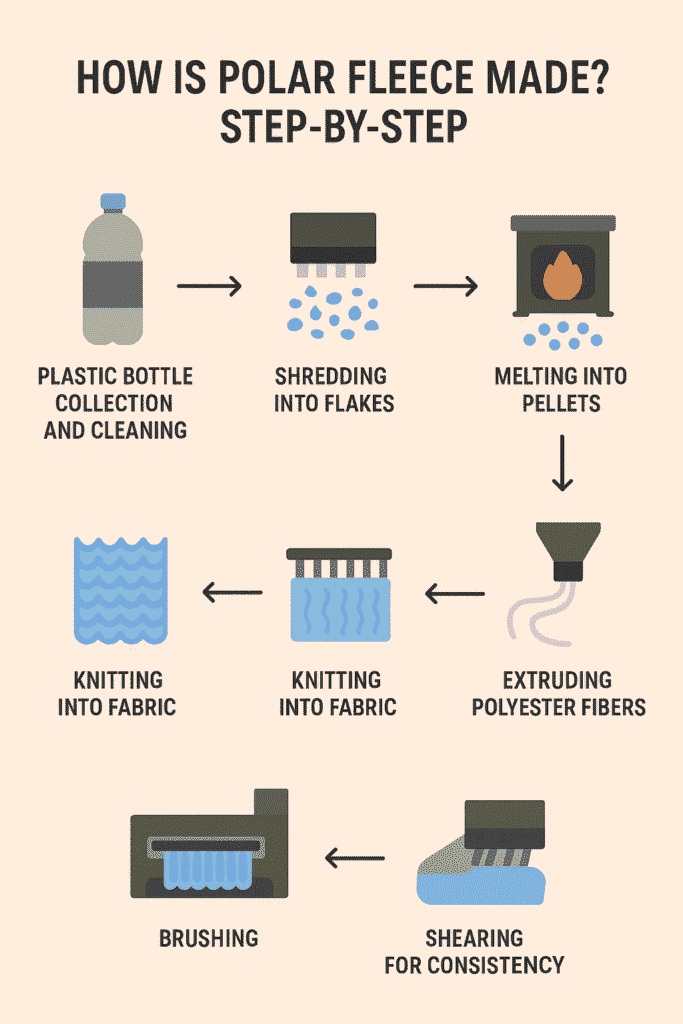

How Is Polar Fleece Made? Step-by-Step

Collecting and Sorting Bottles

Factories obtain first plastic bottles (made of plastic PET, clear PET and coloured PET). Workers remove bottles from conveyors and take off caps, labels and all non-PET trash. The recycling of plastic is categorized as per the texture or color of plastic so that the numbers of the plastic along with the composition of the plastic are easily distributed.

Washing and Shredding

Then, the tidy bottles are sterilized in hot baths, and after that crushed into fine flakes. These plastic flakes get a thorough washing to ensure there are no contaminates or left over residues. Clean, shredded PET is now clean and in a pelletized form and ready to melt.

Melting and Spinning Yarn

The washed PET flakes are then melted and squeezed through spinnerets to give thin polyester filaments. These are spun, twisted, and through spinning machines a continuous yarn is obtained. The yarn is crimped (texturized) and dried to cement strength and loft and spun into thicker yarns on spinning frames.

Dyeing and Knitting Fabric

The polyester may be dyed in bulk prior to knitting. Yarn of clear or transparent or light-colored bottles is color-dyed in light colors; greenbottle yarn is dyed dark in that way. The dyed dried yarn is then set to knitting machines producing rolls of knitted polyester cloth.

Brushing (Napping) the Fabric

The knitted cloth is rendered familiar fuzzy texture by passing through a Napper- a machine that has metal hooks or bristles that brush up the fibers. Brushing causes a dense film of thrash polyester to come out on the surface. This napped stack traps the air and makes polar fleece feel plush and wooly.

Shearing and Finishing

Lastly, fuzzy surface is sheared until at an equal height. Too long fibers will be cut and only even-looking pile will be left. The complete base fabric of fleece is cut and stitched into garments. This is done through brushing and shearing so that each fleece garment will have a uniform fluffy loft.

Key Properties of Polar Fleece

- Insulation: The lofty, fluffy pile of polar fleece holds warm air next to the body. This gives it great insulation properties making it probably better than even wool because of its insulation capacity per ounce of weight gained.

- Lightweight: Polar fleece is lightweight compared to wool hence offering warmth but not the weight. You have a great deal of heat retention with a minimum of bulk to the fabric.

- Breathability: Although polar fleece is a warm piece of clothing, it lets the moisture vapor through. The structure of its form also develops small air cavities thereby enhancing air circulation which helps prevent overheating.

- Moisture-Wicking: The hydrophobic polyester fibers wicks the moisture off the skin and transports it to the outside surface, where it evaporates. This will leave you sweat free and free to move.

- Durability: Polar fleece is quite durable. The fibers are wear- and abrasion-resistant and numerous fleeces are not prone to pilling. Good fleece stands up to repetitive washing and still does not lose its loft.

- Softness: Polyester fleece is so soft that it is hypoallergenic. The modern finishes caress it to the point of being silky. In general, fleece is warm and comfortable next to the skin, easy to wear, similar to a plush wool sweater.

Types and Diversities of Fleece

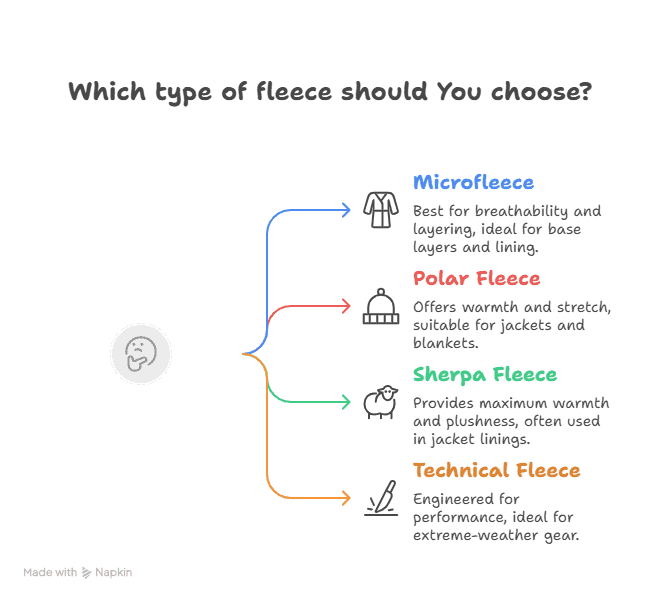

Microfleece

The lightest and the thinnest fleece is microfleece. It is frequently less than 100 gsm. Microfleece is highly breathability and soft which is made of ultra-fine polyester fibers. It is absorbent and quick to dry, so it is suited as lining fabric and base layers of exercise gear. It does not bulk out as much as thicker fleece, and therefore layers well under other tops.

Polar /Polar Plus Fleece

Classic “polar fleece” (commonly referred to as Polar Plus) is a mid weight material (normally 100-300 gsm). It is plop-piled on both, or one side. This is a stretchable fleece, which offers plenty of warmth and usually found in jackets, sweat shirts and blankets. It is denser than microfleece, which keeps more heat; it is also thick. Fleeces are commonly marketed by brand on a weight basis (e.g. Polartec 100, 200, 300) as an indication of warmth.

Sherpa/Furry Fleece

Sherpa fleece A long pile, so-called faux-shearling polyester fleece. Its look is very fluffy and wool-like so it is called after the woolly clothes of Sherpa people. Sherpa is 100% synthetic, made of mostly polyester, though the end result is made to be thick with a curly pile. It is very warm and soft (and commonly placed in linings of jackets). Practically, the term “sherpa fleece” tends to refer simply to a thick, plush pile fleece that is even loftier than ordinary polar fleece.

Technical Fleece

Technical or high-performance fleeces are specialty fabrics by brands like Polartec®. For example, Polartec® Power Stretch™ fleece is engineered for 4-way stretch and moisture management in base layers. WindPro™ fleece uses a tight knit to block 4× more wind than normal fleece while still breathing. Thermal Pro™ fleece comes in various textured finishes (grid, waffle, or high-loft) for extra warmth-to-weight efficiency. These technical fleeces often have proprietary weaves or coatings for wind resistance, durability, or extra stretch and are used in extreme-weather outdoor gear.

Pros and Cons of Polar Fleece

Pros

Offers superb warmth but it is lightweight.

Outdoor quick drying and breathable.

Cost effective against natural wool.

Machine washable and not fussy.

Cons

Pilling: There are minuscule balls of fabric that show up due to friction, and it decreases smoothness.

Environmental Effect: Washing put microplastic in waterways. Such solutions as Guppyfriend bags and Cora Balls exist.

Flammability: Melts when a high heat is applied to it, so it is dangerous in front of fire.

Wind Resistance: Not a windproof naturally, it will need shell layers.

Polar Fleece vs. Other Fabrics

Polar Fleece vs. Wool

Both fleece and wool insulate well. However, polar fleece is synthetic, so it’s much lighter and dries faster than wool. Fleece also breathes and wicks moisture better than wool. On the downside, wool is natural and biodegradable, whereas fleece is petro-based. In general, fleece offers warmth without weight and is easier to wash, while wool can stay warm when damp.

Polar Fleece vs. Cotton

Cotton fleece (like a sweatshirt) absorbs water and loses insulation when wet. In contrast, polyester fleece retains warmth even if damp. Polyester fleece is also lighter and dries much faster than cotton. Cotton feels soft, but it can get cold and clammy with sweat. For consistent insulation and quick-drying performance, polar fleece outperforms cotton fabrics in cold or active conditions.

Polar Fleece vs. Sherpa (Fleece)

Sherpa is basically a thicker, fuzzier version of polyester fleece. Both are made from synthetic fleece fibers, but sherpa has a much longer, curly pile. This makes sherpa extra warm and plush. In practice, sherpa and polar fleece are often the same material type, just in different pile lengths. If you see “sherpa,” expect a very fluffy, wool-like interior – but it’s still polyester.

Polar Fleece vs. Synthetic Insulation (like PrimaLoft)

PrimaLoft and similar “puffy” insulations are lofted synthetic fills, not woven fabrics. They tend to be warmer and more compressible than fleece per ounce. As one expert notes, Primaloft jackets pack small, resist wind, and are lighter weight than fleece layers. However, fleece is more breathable and comfortable next to skin, so it often serves as a midlayer or casual layer, while PrimaLoft is used as high-performance insulation in jackets. In summary, Puffy insulation > warmth-to-weight, fleece > comfort and breathability.

Care and Maintenance Instructions

- Washing: Wash polar fleece always in cold water on gentle cycle. Use a gentle detergent and don’t use a fabric softener which will clog up your fibers. To reduce abrasion turn fleece inside out or wash in a mesh bag.

- Dry: Low heat tumble dry or hang to dry. High heat can melt or shrink fibers that make up fleece so be cool. Take note fleece must be removed straight away to reduce static.

- Eliminating Pills: If they occur (small pills) use a fabric shaver or pilling comb to remove them carefully. You can also use a lint roller to pick up stray fuzz running it over the surface.

Environmental Impact and Sustainability

Polar fleece can be recycled (often re-using old plastic) which helps to combat landfill waste. This is its greatest sustainability strength Nevertheless, the disadvantage is microplastic pollution. Each wash results in releases of fibers to water systems Washing bags, laundry balls or a more advanced filter reduce this issue.

Some brands, such as Patagonia and Polartec (R) are even working on more environmentally-friendly fleece. They have high percentages of recycled fibers and carry out research to lessen the fiber shedding. This is indicative of increasingly demand of eco-friendly textiles.

Conclusion-

Polar fleece is more than just a cozy fabric. It is a product of innovation that transforms plastic waste into cozy warmth. From its invention in 1979 to today’s eco-friendly versions, fleece has changed the way we dress for cold weather.

Although there are limitations— – such as pilling, flammability, and environmental impact— – the benefits outweigh the drawbacks. With proper care and careful washing, it remains one of the most practical fabrics for modern life.

In the future, sustainable fleece will play a key role in combining comfort, affordability, and environmental impact.

Read More>> About Coral fleece fabric.

FAQs

Polar fleece fabric is made entirely of polyester (PET). It’s essentially plastic fabric – often spun from recycled plastic bottles – that’s been knitted and brushed to create a warm, fluffy pile.

Yes. Polar fleece traps a lot of body heat thanks to its raised pile. At the same time, it’s breathable and moisture-wicking, so it keeps you warm and allows sweat to escape. You get warmth without feeling clammy.

Wash it gently in cold water on a mild cycle. Avoid fabric softeners and hot water, which can damage the fibers. Tumble dry on low heat or hang to dry. This helps prevent shrinking, static, and pilling.

Polar fleece often uses recycled plastic bottles, which is a plus. However, it does shed microscopic fibers when laundered. To minimize impact, you can wash fleece in a filter bag or use a Guppyfriend/Cora Ball to catch fibers. Also, look for brands using recycled fleece or special low-shed finishes.

I never realized how much of an impact the recycling process has on the creation of polar fleece! It’s fascinating to learn that the material starts as plastic bottles before being turned into something so warm and soft. It really highlights the potential of sustainable manufacturing in fashion.

Custom solutions delivered, personalization makes the difference. Tailored service excellence. Tailored appreciation.

[…] Wash in cold water: I use cold water and a gentle cycle when I wash my fleece. Hot water can damage the fibers and cause more pilling. I pick a mild detergent and skip fabric softeners. Fabric softeners can clog the fibers and make pilling worse. […]