Introduction-

The warm blanket in which you cover yourself during a cold night, or the fabric of the lightweight jacket that you take with you when going hiking; both are probably produced using fleece. Fleece is sometimes confused with wool, being thought of as directly coming off sheep as well. The term naturally misleads others into visualizing animal natural fiber. However, there is a catching news: fleece is not what has generally been believed.

Fleece is a very common cloth towards the trends of clothing as well as domestic textiles. It is soft, warm, durable, and thus, is popular as an outdoor fabric and blanket, as well as sportswear. But you may be shocked by the origins. We will reveal the actual answer to what is fleece made of, discuss the manufacturing process, compare the material with the natural fabrics, and investigate its environmental impact in this article. At the end of it, you will have everything you need to know about this interesting fabric.

What Is Fleece Actually Made From?

The shocking truth is that, Modern fleece is polyester, a man-made polymer created with a petroleum product (crude oil). Rather than shaving off sheep or goats, fleece is constructed out of fibers made of plastic.

Fleece was not made out of animal wool, as it is an entirely synthetical material with polyester as its main component.

It is here that many people become surprised. Wool is a natural product while fleece is produced in factories and laboratories. Better yet, fleece is also recyclable, which means that fleece that has already been discarded can end up becoming the apparel you wear at home, to make it useful once again.

Its softness and breathability, coupled with ease of care have made fleece a popular staple fabric of contemporary fashion. To fully enjoy it we need to understand how it is made.

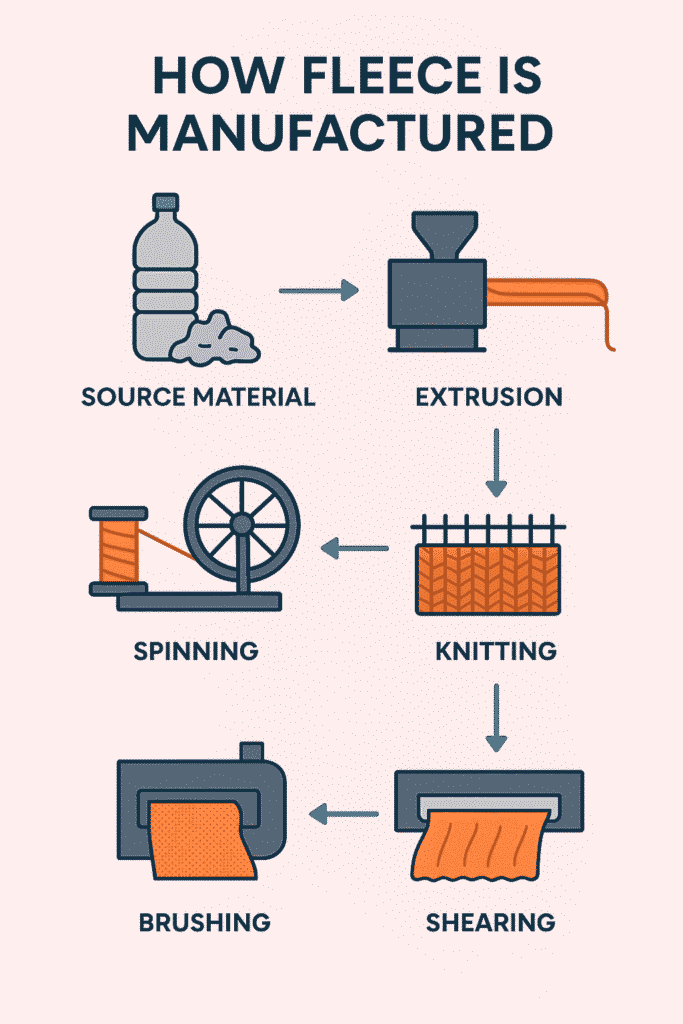

From Plastic Bottles to Cozy Fabric: How Fleece is Manufactured

The path of fleece through the process of getting a soft fabric is rather interesting. It may be simplified into steps.

Source Material: PET (Polyethylene Terephthalate)

PET is a form of plastic found in soda and water bottles where the beginning point of fleece starts. The manufacturers can use brand new polyester pellets or even utilize discarded plastic bottles. During recycling, bottles are gathered, separated and washed and then are reduced to flakes. The flakes are melted forming polyester chips that can be used as a foundation fleece.

Extrusion

After polyester is made, it undergoes extrusion in which the melted substance is forced through extremely small spinnerets. The liquid polyester is forced through special metal nozzles with holes, called spinnerets, which makes the polymers into long hair-like filaments. These fine threads are gradually cooled and solidified to make strong fibers. The extruder process guarantees that the fibers are even in thickness, and are best suited to be converted into a yarn.

Spinning

The resultant polyester filaments are then stretched, twisted in the spinning process. This adds strength, flexibility and durability to the fibers and enables them to stand up to everyday wear. The twisting resembles the appearance and texture of natural fibers although they are man-made. The process also aids in the regulation of the softness and the density of the end fleece material.

Knitting

The polyester yarns are there knitted into big sheets of fabric. One of the factors that most influences the thickness, stretchiness or light weight of the fleece is knitting. Depending on the pattern, it can be single-knit lighter fleece or double-knit heavier, warmer varieties of fabric. This knitted cloth serves as the base which is then subjected to special process to give it the fluffy nature of fleece.

Brushing

The step that makes fleece soft and cozy is brushing. In this process, the knitted fabric is wiped through large cylindrical brushes which have fine tooth of metal. The brushes spread the fibers on the surface and break them creating the lift away in a pile to create a plush insulating surface. This raised material traps air which enhances insulation and gives fleece great warmth, without increasing weight.

Shearing

The brushed fleece is then subjected to shearing, in order to provide it with a smooth, even treatment. The raised fibers are then awkwardly edged to the same height such that the fabric material feels smooth and uniform all over the material. Shearing also prevents too much bulkiness or un evenness of the fabric. The final product is a deliciously smooth, warm and a very versatile fabric that can be used in jackets, blankets… and many other products.

By doing this, an otherwise unfit plastic bottle is made into an acceptable breathable and warm textile. Fleece manufacturing demonstrates the capacity of human creativity to transform any ordinary waste into practical and comfortable materials.

Types of Polyester Fleece

There are several varieties of polyester fleece, each suited to different uses. They differ by weight, pile length, or blend:

Polar Fleece

Polar fleece is the classic, all-purpose fleece. It has a double-sided pile (brushed on both sides) for extra warmth. Polar fleece is ubiquitous in jackets, blankets, and linings. It’s designed to mimic the insulating quality of wool but is lighter and easier to care for. Polar fleece was first developed in the 1970s (by Polartec) as a synthetic wool substitute. Today, any midweight fleece you see is often called “polar fleece.”

Microfleece

Microfleece is a lighter, thinner version of polar fleece. It is usually double-sided but with a very fine (short) pile. Microfleece is extremely soft and has a low profile – it doesn’t puff up much. Because it weighs less (often under 6 ounces per square yard), microfleece is ideal for base layers and activewear. It insulates well for its weight and packs down small. However, it is not as warm as thicker fleeces. In short, microfleece is a “micro” version of standard fleece – great for layering under a jacket or wearing during exercise.

Sherpa Fleece

Sherpa fleece (also called faux-sherpa or boa fleece) mimics the look and feel of a sheep’s wool fleece. It is made of polyester but has a curly, looped pile on one side. Sherpa is typically one side fluffy like a sheep’s wool, while the other side is a smooth knit. It is extremely soft, warm, and plush – picture the lining of a cozy winter coat. Sherpa fleece is very bulky and fluffy, making it excellent for hoodies, linings, and decorative trims. Fashionably, it has “blown up” in popularity for hats, vests, and jackets because of its very visible, wool-like texture. It tends to shed a bit of fluff with wear (though modern Sherpas are engineered to hold their pile).

Blizzard Fleece

Blizzard fleece is warmer and also thicker than standard polar fleece. It has a fluffy velvet texture and is commonly applied to make no-sew blankets, winter garments, and outer clothes.

All types of fleece carry specific advantages enabling manufacturers to target a broad consumer base-lightweight and sporty to heavyweight and warm.

Fleece vs. Wool: The Ultimate Comparison

Many people wonder whether fleece or wool is better. Let’s compare them across key categories:

| Feature | Fleece | Wool |

|---|---|---|

| Warmth | Excellent warmth-to-weight ratio | Naturally warm, even when damp |

| Moisture Wicking | Repels water, dries quickly | Absorbs water but stays insulating |

| Breathability | Good, but less than wool | Highly breathable |

| Weight | Lightweight | Heavier in comparison |

| Durability & Care | Machine washable, easy to care for | Requires gentle washing or dry cleaning |

| Cost | Affordable and widely available | More expensive due to natural sourcing |

The Eco-Dilemma: The Issue of Microplastic

A controversial topic in fleece has to do with its effects on the environment.

One of the positives is that fleece is produced using recycled bottles, and therefore less plastic is found in landfills. Brands such as Patagonia have brought this to industry, where it recycles millions of bottles into clothing. Our system of recycling lessens the need to produce virgin polyester and decreases pressure on the environment.

The big problem with fleece however, is that when washed, microplastic fibers are shed. All these fibers flow within wastewater through systems, and find their way to rivers, oceans, and even through our food chain. It has been discovered that microplastics can be detrimental to the marine life and even human health.

There are solutions to that:

- Wash wash fleece less frequently to minimize shedding.

- Use a bag of Guppyfriend or Cora Ball to collect the fibers.

- Invest in a finer-grade of fleece that does not lose as much hair over the months.

The eco-dilemma implies both, that fleece is useful and harmful. Although it shrinks some waste, it poses some new challenges. The practice of responsible consumerism will be a huge step

The Advantages and the Disadvantages of Fleece Fabric

Advantages

- Soft and very comfortable

- Light inbergaten warm

- Breathable and very fast drying

- Long lasting and hard wearing

- No problem to maintain (washable)

- Cost effective substitute to natural ones

Disadvantages

- This is composed of petroleum based resources

- Microplastic is shed in releasement during laundry

- Unless treated, Flammable

- Will hold odors longer than wool

- Less environmentally friendly than the natural fibers

Conclusion-

Fleece is not this natural sheep wool that many people think it to be. Rather, it consists of a man-made material comprising mainly of polyester and often derived out of used plastic bottles. Its softness, and warmth and cheapness have made it one of the most popular fabric in the globe.

But ignorance of what fleece is composed of puts us in a better position to make decisions. Although most of the benefits of the use of fleece can be discussed, it is associated with such environmental issues as microplastic pollution. Recycled fleece is an area that someone can be able to balance comfort and sustainability by choosing to use recycled fleece, washing it responsibly and by using it wisely.

All in all, fleece is the ideal combination of human technology combined with usefulness and practicality–a garment made of plastic but warm and comfortable to wear.

Read More>> About the shrinkage of fleece fabric.

FAQs

No, fleece is not a natural fabric. It is an artificially produced fabric, made out of polyester that is based on petroleum or used plastic bottles. Fleece is an industrially manufactured product rather than a natural product as is wool.

Recycling of fleece is possible, but the process does not always exist on a wide scale. There are other companies, like Patagonia, which have recycling programs where old items made out of fleece can be recycled. Recycling will also aid in the reduction of waste and makes used fleece products have a second life.

To prevent pilling, especially for fleece, all the fleece set should be turned inside out and washed. Choose a sensitive wash with cold water and mild detergents & fabric softeners. To get the best results air dry the fleece or use a low tumble to keep it soft.

Technical fleece is built for performance – ensuring warmth, moisture management and durability for the outdoor or athlete. Fashion fleece compared is designed mainly for comfort and for fashion and is commonly used in casual projects such as hoodies, loungewear or trendy jacket. Both are for different task dependent upon your need.

Fleece and wool perform both similarly in terms of warmth provisions, but slightly differently. Fleece is warm considering its weight to weight ratio hence it is lightweight yet warm. Wool on the contrary, keeps the heat even in wet weather which makes the latter superior.

Premium Manhattan service, exactly what Tribeca living requires. Using for our office space too. Outstanding Manhattan team.

It’s interesting how the nameBlog comment creation ‘fleece’ makes many people assume it comes from animals, when in reality it’s often made from recycled PET bottles. I think the point about microplastics is especially important, since it shows that even fabrics marketed as sustainable can have hidden downsides. It would be great if more discussions like this helped people weigh comfort and practicality against environmental impact.

[…] notice that most fleece jackets use synthetic fibers. Polyester is the most common material. Manufacturers create different types of polyester fleece, such as […]