Textile enthusiasts appreciate modal fabric for its softness and breathability combined with its durability. Understanding modal fabric requires us to answer the question many people ask before fully accepting it: “is modal fabric toxic?”.

Modal represents a semi-synthetic fiber that originates from beech tree pulp. The rayon family includes modal which is closely related to both viscose and lyocell. Modal fabric originates from wood pulp but isn’t completely natural because the raw material requires chemical transformation to produce wearable fibers.

This semi-synthetic fabric demonstrates superiority over cotton, viscose, and polyester by delivering better softness, stretchability, and shrinkage resistance. Modal provides a breathable natural comfort while polyester’s plastic base can result in skin irritation.

Modal appears in various products including clothing items like underwear and loungewear as well as bedsheets, towels, and activewear. While modal’s silky texture makes it perfect for everyday use we should explore what happens during its manufacturing process.

How Modal Fabric Is Made

Knowing the manufacturing process of modal assists in determining its safety and potential toxicity. We will examine every phase of the process thoroughly.

Harvesting Beech Trees

The sustainable management of beech tree forests in Europe serves as the starting point of this journey. Trees that regenerate naturally demand fewer irrigation methods and fewer chemical applications than cotton plants.

Pulping the Wood

Workers process harvested beechwood by chopping it and soaking it in sodium hydroxide which acts as caustic soda to separate cellulose. The chemical reaction produces a thick pulp solution by breaking down the wood structure.

Chemical Treatment & Fiber Formation

The cellulose pulp undergoes a transformation into viscose solution after treatment with the hazardous solvent carbon disulfide (CS₂). The process remains essential yet contentious because of the associated health hazards.

Spinning into Fibers

Through spinnerets the viscose solution gets forced into a sulfuric acid bath which solidifies it into long strands. After solidification into strands through a sulfuric acid bath these fibers undergo washing followed by bleaching and stretching into yarn.

Finishing the Fabric

After drying the modal yarn, manufacturers cut it and often mix it with fibers such as cotton or elastane. Manufacturers choose to introduce both fabric softeners and dyes during this production phase.

Environmental Impact of Production

Unregulated chemical steps lead to environmental pollution. Leading modal producers integrate closed-loop systems to capture and recycle solvents. In production, Lenzing manages to retrieve approximately 99% of its carbon disulfide. Mills located in developing regions often release untreated waste into the environment. Effluent treatment processes and sustainable sourcing practices such as FSC-certified wood help reduce the environmental footprint of modal production.

Is Modal Fabric Toxic? – Key Concerns

Context plays a crucial role when people inquire about the toxicity of modal fabric. Modal fabric maintains its composition primarily of cellulose (plant fiber) and shows no inherent toxicity toward people in its final state. Manufacturers promote modal as a soft fabric that is suitable for sensitive skin. OEKO-TEX® testing is wise: Modal fabrics that meet Standard 100 pass examinations for more than 1,000 harmful substances before receiving safety certification. A garment made from certified modal fabric presents no health hazards. The primary issues with modal fabric stem from leftover chemical residues rather than the fiber itself.

The manufacturing process involves harsh reagents such as sodium hydroxide and softeners which can lead to poorly processed modal fabric retaining irritants. High-quality manufacturers complete thorough rinsing and neutralizing procedures on their fabrics. Persons with delicate skin conditions or parents of babies often choose modal fabrics that hold OEKO-TEX or GOTS certification because these certifications ensure fewer chemical residues remain. High-quality modal fabric generally contains fewer contaminants than both plain viscose and “bamboo” rayon produced by similar processes. The main hazards of modal fabric relate to insufficient processing and finishing steps. While modal fabric created with proper methods is safe and non-toxic, modal without certification could still contain trace chemicals. Choosing reputable, certified modal minimizes any worry. Choosing certified modal sources results in minimal health and ecological footprints.

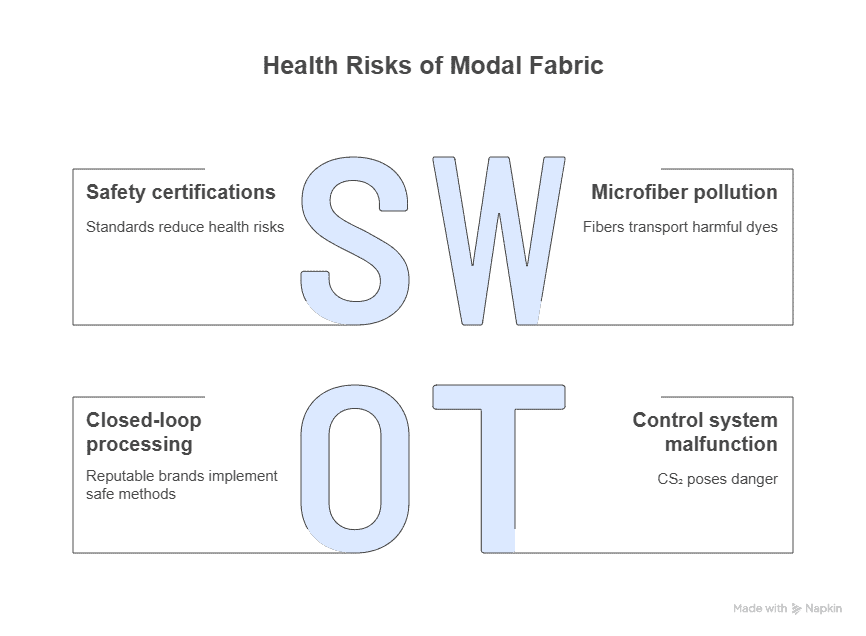

Potential Health Risks of Modal Fabric

Production Toxins

Carbon disulfide (CS₂) poses the greatest health threat during modal production. Historically research established CS₂ as a toxic solvent which caused neurological damage in workers who handled it. European modal manufacturers today successfully capture and recycle almost all carbon disulfide while it still poses a danger when control systems malfunction. The amount of residual CS₂ in modal fiber is negligible when it arrives at your hands. Studies show that carbon disulfide evaporates away throughout processing which results in finished fabric containing nearly pure cellulose.

Microfiber Pollution

Modal releases microfibers into waterways while it undergoes washing similar to other textiles. The cellulose composition of these fibers makes them degrade more efficiently than plastic-based polyester. Research indicates that rayon deteriorates more rapidly than cotton in soil while silverfish can safely ingest rayon fibers. When these fibers escape into water systems they may transport harmful dyes or chemicals. Environmental organizations express concern about microfiber pollution impacting all types of fabrics. You should reduce microfiber shedding by selecting gentle wash settings and using mesh bags during washing cycles while preventing excessive spinning. Following these methods will capture fibers and lessen pollution levels.

Certifications and Standards

Certifications verify that modal fabric meets safety and environmental standards. Materials with OEKO-TEX® Standard 100 and GOTS labels have undergone testing against harmful substance lists. When packaging displays FSC or PEFC certification it indicates that the wood pulp was sourced from forests that are managed sustainably. Reputable brands that produce Lenzing™ Modal or TENCEL™ Modal products tend to implement safe closed-loop processing methods. These standards greatly reduce potential health risks.

Environmental Impact & Modal Fabric Toxicity

Modal fabric has some eco-friendly aspects. It is biodegradable, unlike synthetic fibers. Modal garments will break down over time when they are discarded into natural environments. Studies reveal that rayon (modal) fibers decompose more quickly in the soil compared to cotton. The production of modal cotton demands substantially less water than conventional cotton production which presents a sustainability benefit. However, the production process must be well-managed. Mills that produced viscose or modal fibers without adequate treatment contaminated rivers in earlier years. As a result, organizations such as FSC and CanopyPlanet have begun auditing companies that produce cellulosic fibers. Lenzing received top marks in Canopy’s “Hot Button” 2020 report because of their certified wood sourcing and clean production methods. Choose TENCEL™ Lyocell for a more eco-friendly textile choice. A non-toxic solvent breaks down wood pulp and recovers 99.8% of it.

Lyocell mimics the texture of modal while utilizing a cleaner production method. Alternative sustainable materials include organic cotton along with hemp and linen as well as recycled fabric options.

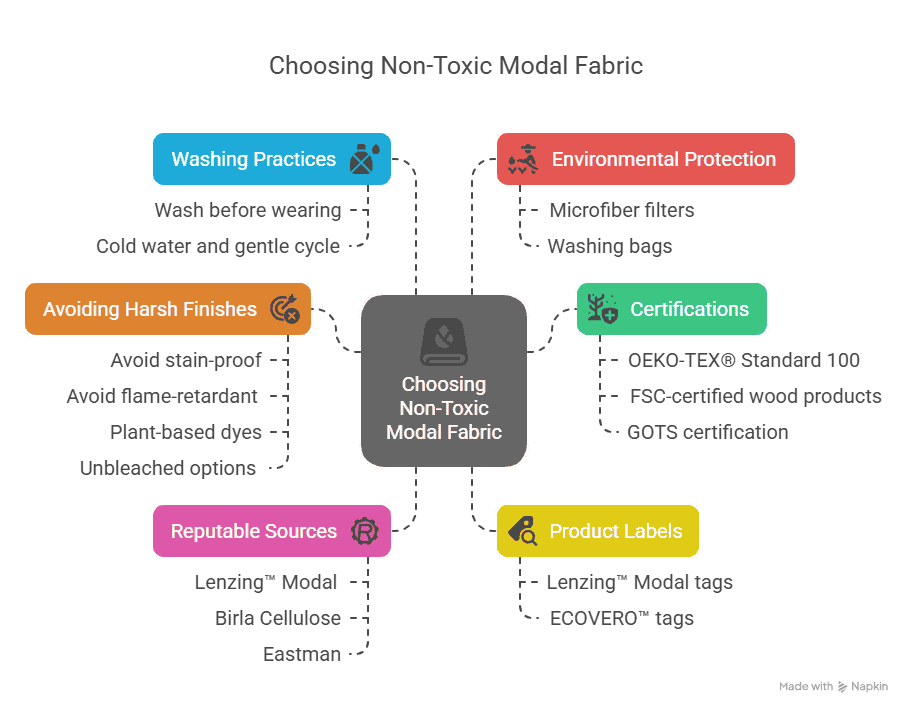

How to Choose Non-Toxic Modal Fabric

- Check for certifications: Safety indicators include OEKO-TEX® Standard 100 (particularly Class 1) and FSC-certified wood products. The GOTS certification gains importance when organic cotton is blended with modal fibers.

- Trust reputable sources: Search for fabric labels showing Lenzing™ Modal (TENCEL™ or ECOVERO™) or any reference to Lenzing. Suppliers such as Birla Cellulose and Eastman continue to advance their production standards.

- Inspect product labels: Fabrics that have tags indicating “Lenzing™ Modal” or “ECOVERO™” adhere to superior quality standards.

- Wash new items: Always wash new modal clothes before wearing. This removes any trace processing agents. Use cold water and a gentle cycle.

- Use microfiber filters: Install a lint filter or use a washing bag to catch fibers and protect water quality.

- Avoid harsh finishes: Avoid purchasing clothes labeled as either stain-proof or flame-retardant. Formaldehyde and PFAS along with additional toxins are common contents in these types of clothing. Modal clothes that use plant-based dyes or remain unbleached are safer options.

Myths vs. Facts About Modal Toxicity

- Myth: Modal is a completely “natural” fabric.

- Fact: Modal starts as wood but requires extensive chemical treatment including caustic soda and carbon disulfide. It is semi-synthetic, not like untreated cotton.

- Myth: All modal is eco-friendly.

- Fact: Modal becomes an eco-friendly fabric when it is produced in a certified mill that utilizes a closed-loop system. Unregulated modal production processes generate pollution levels equivalent to those produced during standard viscose manufacturing. Always check for sustainable production claims.

- Myth: Bamboo fabric is inherently safer than modal.

- Fact: “Bamboo” labeled textiles often turn out to be rayon made from bamboo pulp. They use the same chemicals as modal. The processing procedure determines their safety instead of the raw material used.

- Myth: OEKO-TEX certification means zero chemicals.

- Fact: The OEKO-TEX Standard 100 certification permits only minimal trace chemical levels. Certified modal maintains a high level of safety standards although it contains trace chemicals. The label ensures all chemicals remain under strict health limits.

Conclusion-

After examining modal fabric closely, the verdict is this: modal itself is not inherently toxic. The fabric qualifies as regenerated cellulose and appears safe in clothing applications since no known health risks are reported. Professional evaluations classify rayon/modal as having minimal cancer and allergen risks. Environmental concerns and manufacturing practices present risks rather than wearing modal fabric itself. Select modal from sources that provide trustworthy certifications to reduce potential risks. The manufacturing processes of products with OEKO-TEX® Standard 100 labels or brands like Lenzing™ (TENCEL™ Modal) involve cleaner methods. Always wash new modal clothing before wearing and use gentle laundering. Both consumers and clothing brands are now paying closer attention to the chemicals used in textiles. Consumer demand for transparency requires modal producers to reveal their production methods.

Education is key: Knowledge about modal fabric’s life cycle provides consumers with information to make better safety decisions. Fashion industry professionals need to support cleaner production and obtain certifications to satisfy consumer demand.

Safer Alternatives: For those who remain concerned about toxicity and sustainability issues, TENCEL™ Lyocell that uses a non-toxic solvent and natural fibers including organic cotton, linen, and hemp could be viable alternatives. The production of these materials requires fewer toxic substances and results in products that break down readily in the environment. Modal fabric remains free from carcinogenic elements and overt toxicity if produced correctly. Proper certifications and maintenance allow modal to serve as both comfortable and environmentally friendly clothing fiber.

FAQs

Is modal fabric carcinogenic?

Certified modal fabric is not carcinogenic. Exposure to carbon disulfide poses health dangers for production workers.

Can modal fabric cause skin irritation?

Many people refer to modal as a hypoallergenic fabric that offers a gentle touch. Its fibers are smooth and usually non-irritating. Sensitive skin may become irritated if the modal fabric contains rough dyes or finishes. Selecting modal with OEKO-TEX or GOTS certification will help reduce allergens for safety.

Does modal fabric shrink or stretch easily?

A: Modal is more stable than regular rayon. It can usually be tumble-dried without damage. Proper laundering methods prevent substantial shrinkage of this fabric. While modal fabric exhibits natural elasticity it keeps its shape firmly.

Is modal fabric safe for baby clothes?

Yes, if produced safely. Modal’s softness is great for babies. The product must meet OEKO-TEX Standard 100 Class I certification for baby items. Modal baby clothes with certification contain minimal residues ensuring safety for sensitive skin.

This was aModal fabric toxicity comment helpful breakdown of how modal is made and the potential concerns around chemical processing and microfiber pollution. I appreciate that you also covered how certifications can help consumers identify safer options—it’s a detail that often gets overlooked in fabric discussions.

Thank you so much for your kind words! I’m really glad you found the breakdown helpful. It’s true—certifications often get overlooked, but they play a big role in helping consumers make safer, more informed choices.

I have a tshirt 60percent cotton

And 40

Percent modal Benelton I love it but

I over heat in it , and have to take it off..

That only usually happens to me with acrylic ; I feel it’s not natural at all if it’s made out of saw dust which is toxic !

I know it’s highly processed to turn it into fabric but not natural enough for me !

Thank you for sharing your experience! Modal is technically semi-synthetic—while it’s made from natural sources like beechwood, it does go through heavy processing, which can affect how it feels and performs. Everyone’s skin and comfort level are different, so it makes sense that it might not work well for you. I appreciate you adding your perspective

I really appreciate how this post breaks down the production process of modal fabric and sheds light on the potential chemical concerns. One aspect I’d love to see explored further is how consumers can verify whether the modal they’re buying meets safer certification standards like OEKO-TEX or FSC. It’s great to see more awareness around the environmental and health impacts of textiles.

[…] uses fewer chemicals than viscose rayon. But it still needs chemicals like sodium hydroxide and carbon disulfide. These chemicals can hurt the environment if not handled right. Some companies use closed-loop […]

So basically, if the modal fabric doesn’t have a certificate, it’s like taking a dive into a mystery pool—could be refreshing, could be a toxic swamp. Who knew deciding on pajamas could be such a thriller!

I love how modal touted as ‘breathable’ really just means we’re taking a gamble on how many chemicals are still hanging around. It’s like trying to choose the least questionable piece from a secondhand store—good luck!

Really appreciated the breakdown of how modal is produced—from beech tree harvesting to the chemical processing steps. It’s helpful to see the discussion around potential toxins balanced with info on certifications and eco-friendly practices. The part about microfiber pollution was especially eye-opening—definitely something I hadn’t considered before.

Your investigation into modal fabric’s safety is so thorough! The way you broke down the manufacturing process really helped me understand the potential chemical concerns. I especially appreciated your comparison between different producers’ environmental standards – that Lenzing example was enlightening. Your tips for identifying truly non-toxic modal are practical and will definitely influence my future fabric choices. That final reminder about checking OEKO-TEX certifications is advice I’ll be using!

이것을 우리와 공유해줘서 실제로 고맙습니다, 당신은 논하는 것을 실제로 이해하고

있습니다! 북마크했습니다. 제 사이트도 상담해 주세요 =).

우리 사이에 링크 교환 계약을 맺을 수 있습니다.

Hi to every single one, it’s really a fastidious for me to go to see this web page, it contains valuable Information.

Modal fabric is generally considered safe and non-toxic, as it is made from cellulose derived from beech trees. Its production involves chemical processing, but reputable manufacturers ensure minimal harmful residues. Modal is eco-friendly and hypoallergenic, making it suitable for sensitive skin. Choosing certified brands ensures higher safety and sustainability standards.

This is a helpful explanation of how modal fabric is produced and the possible issues related to chemical processing and microfiber pollution. I value the inclusion of information about certifications, which guide consumers toward safer choices—a crucial detail often missed in fabric discussions.

Your modal fabric safety analysis is spot-on! The OEKO-TEX certification tip is especially valuable. Clear, balanced guidance on eco-friendly versus conventional production methods. Helpful for conscious consumers!

Your modal fabric safety analysis is invaluable! The OEKO-TEX certification tip helps identify truly non-toxic options. Clear comparison of eco-friendly versus conventional production methods. Essential reading for conscious consumers!

This article is super helpful! I always wondered about modal, and it’s interesting to learn it’s semi-synthetic even though it comes from wood pulp. Also, knowing it’s superior to cotton and polyester in some ways, like softness and stretch, is a great takeaway. Thanks for clearing things up!

Vải modal là một lựa chọn tuyệt vời cho những ai yêu thích sự mềm mại và thoáng khí!

good

This article is super helpful

Hey! Check out. It’s a great website. You can turn your PDFs into online links easily. It’s very useful when you want to share PDF files. Try it now and make sharing PDFs a breeze!

Modal fabric is widely regarded as a safe and non-toxic material, crafted from cellulose extracted from beech trees. While its production involves chemical processing, responsible manufacturers typically adhere to practices that minimize harmful residues. Known for its eco-friendly and hypoallergenic properties, Modal is an excellent choice for individuals with sensitive skin. Opting for certified brands ensures compliance with higher safety and sustainability standards, making it a reliable and environmentally conscious option.

Greate! I love Modal so much,alost clothes is powered by Modal

당신이 웹사이트에 쏟은 노력과 상세한 정보를 제시하는

것을 높이 평가합니다. 같은 오래된 재탕 정보를 다루지 않는 블로그를 가끔 만나는 것은 좋습니다.

환상적인 읽기였습니다! 당신의 사이트를 저장했고 RSS 피드를 제 Google 계정에 추가하고

있습니다.

Hi there to all, the contents present at this web page are actually remarkable for people knowledge,

well, keep up the good work fellows.

I appreciate how this post breaks down the production process of modal, especially the balance between its softness and the chemicals used in manufacturing. It’s interesting that while the fabric itself is generally safe to wear, the bigger concern lies in how responsibly it’s produced and whether certifications are in place. I think many people overlook the environmental impact compared to personal health risks, so highlighting both perspectives is really useful.

That was an interesting read! I’ve always been curious about how eco-friendly modal fabric actually is compared to cotton or bamboo. It’s great to see a clear explanation of how it’s made and what makes it more sustainable. Thanks for breaking down the pros and cons so simply — it really helps when trying to make more conscious clothing choices.

Honestly, if you’re worried about modal being toxic, just look for certified options. Skimping on that might mean you’re playing with fire. Not worth risking your health over cheap fabric.

Thank you for sharing this insightful article!

The distinction between fiber safety and factory practices is spot on—modal’s fine to wear, but without closed-loop production and certifications, you’re just outsourcing the risk to workers and rivers.

Wow, this article about modal fabric is super interesting! I never thought about the whole manufacturing process. I wonder if the games on TinyFun are made with this fabric?

I had never thought about all the chemical steps necessary to create modal. I wonder if the clothes I have made of modal are certified

It’s great to see such a comprehensive breakdown of modal fabric’s production and safety. One point I found interesting was the emphasis on microfiber pollution—this is something that gets overlooked a lot when discussing fabric sustainability.

Thanks for this helpful deep dive! I’ve always wondered about modal fabric’s safety. Learning that it comes from beech trees and is semi-synthetic but still soft and durable was really interesting.

Thanks for this helpful breakdown on modal fabric — it’s great to understand the differences between comfort, sustainability, and safety when choosing materials. Always good to be informed before making textile decisions!