The Tencel brand represents a collection of fibers including lyocell and modal. The manufacturing process of these fibers utilizes wood pulp from sources such as eucalyptus, beech, or spruce and they earn recognition for their softness alongside their durability and breathability. Tencel serves as an environmentally friendly option against standard synthetic materials and chemically processed textiles.

The rise in consumer demand for safe sustainable clothing prompts an essential inquiry about “Is Tencel fabric toxic?” The issue involves both individual health and environmental protection. This article examines the scientific facts and production processes behind Tencel to determine its safety for human health and environmental protection.

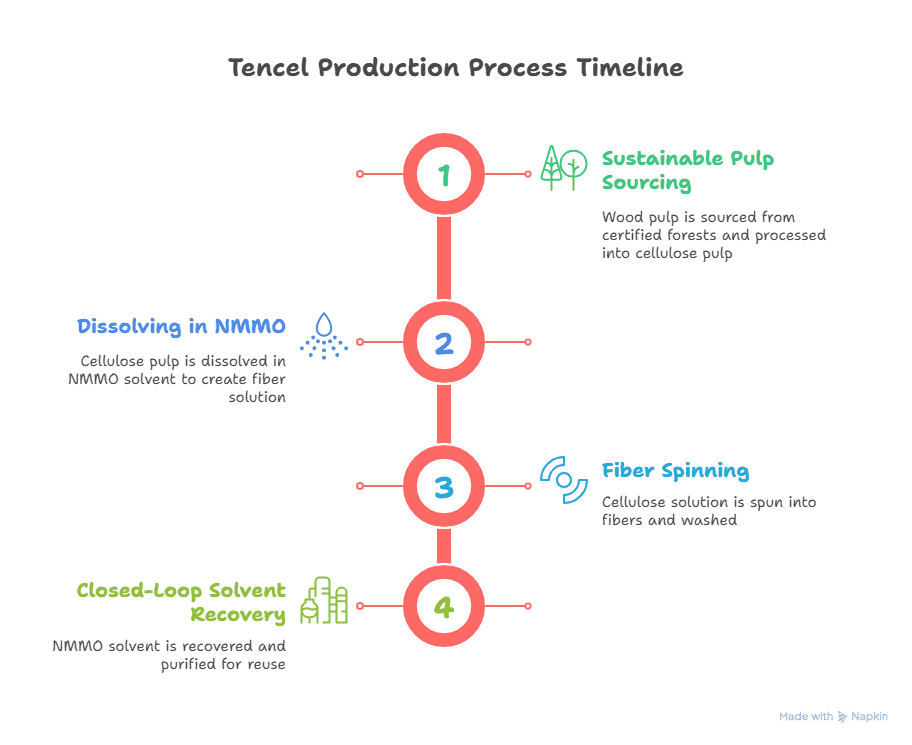

Tencel Production Process

Sustainable Pulp Sourcing

The initial stage of the process involves sourcing wood pulp from forests that have obtained certification. Lenzing obtains cellulose from plantations that follow sustainable management practices which frequently have FSC or PEFC certifications. The forestry plantations utilize fast-growing eucalyptus or beech trees which thrive without significant pesticide application. Raw wood undergoes chipping and drying to produce cellulose pulp that maintains minimal chemical contamination.

Dissolving in NMMO

Wood pulp becomes dissolved when N-methylmorpholine N-oxide (NMMO) acts as an organic solvent. The result of this process creates a thick cellulose solution that can form fibers. The non-toxic and biodegradable properties of NMMO guarantee its safety as a solvent during Tencel production. The Tencel closed-loop system recycles and reuses nearly all of the solvent during this step.

Fiber Spinning

The cellulose solution passes through minute nozzles called spinnerets which produce unbroken filaments. The filaments transform into fibers when they come into contact with the water bath. After the fibers undergo a water washing process to eliminate residual solvent they are stretched and dried to enhance their strength. This stage requires only water and mechanical processing without any heavy chemicals.

Closed-Loop Solvent Recovery

The fiber slurry and the used NMMO solvent undergo separation. The system successfully retrieves approximately 99% of spent NMMO solvent which gets reintroduced into the processing cycle. The closed-loop recovery system stops chemical release while maintaining an extremely clean operation. In the reuse process NMMO undergoes purification to ensure finished fabric contains almost undetectable solvent levels. The treatment of wastewater helps ensure the whole process produces very little pollution.

Chemical Residues & Certifications

Non-toxic Fabric Certifications

Non-toxic fabric certifications accompany Tencel products to show that they contain no harmful residues. The OEKO-TEX Standard 100 certification proves textiles have undergone testing for more than 1,000 harmful substances and received confirmation of their safety for skin contact. Throughout processing The Global Organic Textile Standard (GOTS) limits hazardous dyes and chemicals. Buyers can trust Tencel garments that display these labels because they confirm compliance with stringent safety standards free from prohibited toxic substances.

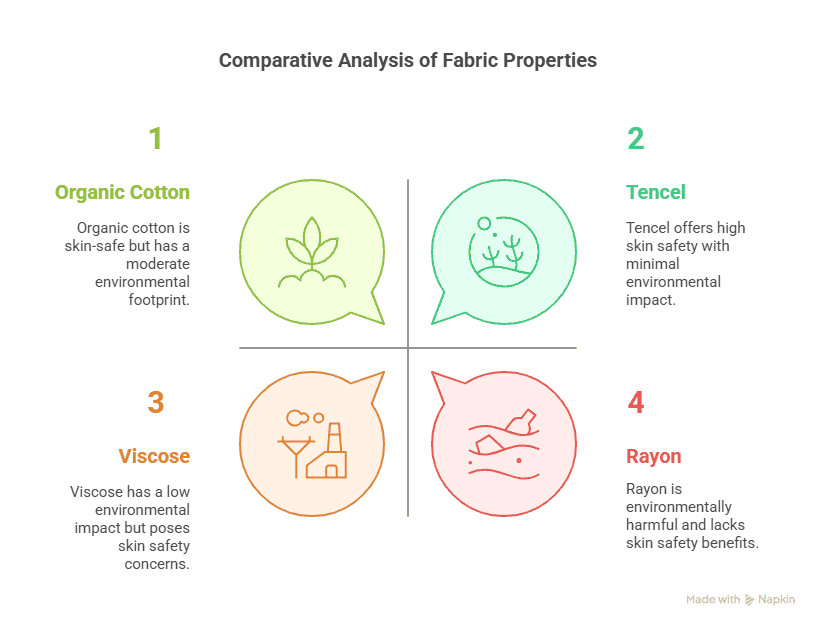

Tencel vs Cotton and Polyester

The Tencel fabric has significantly fewer chemical residues when compared to traditional cotton and polyester materials. Non-organic cotton retains traces of pesticides and fertilizers while Tencel begins with pure wood pulp. According to research overviews Tencel requires less dye than cotton because it comes from production as a pure white material which eliminates bleaching needs. Polyester stands apart as a complete synthetic plastic material which frequently incorporates additional substances. Research shows that polyester clothing contains substantial amounts of phthalates which function as plasticizers, a risk absent in cellulosic Tencel. Certified Tencel fibers possess fewer residual chemicals in comparison to both untreated cotton and polyester fibers.

Skin Safety & Hypoallergenic Properties

Hypoallergenic and Skin-Friendly

Tencel fabrics exhibit hypoallergenic properties and provide a soft touch ideal for sensitive skin. The fibers maintain a smooth frictionless surface that prevents dust mites and mildew buildup alongside other allergens, reducing skin irritation. A clinical study demonstrated that people suffering from atopic dermatitis (eczema) experienced better comfort with lyocell (Tencel) fabrics compared to cotton which caused less skin irritation. Because of its hypoallergenic properties and gentle touch Tencel proves to be a suitable choice for allergy sufferers and those with sensitive skin.

Moisture-Wicking Comfort

Tencel fibers are very moisture-wicking and breathable. A study revealed that participants found lyocell (Tencel) outperformed cotton in both moisture management and temperature regulation. These fibers quickly soak up perspiration and then expel it which keeps the skin tempered and dry. Tencel gains popularity in activewear and bedding markets because it prevents heat and moisture accumulation during physical activity or nighttime rest.

Research and Testimonials

Evidence from clinical research combined with customer experiences confirms Tencel’s reputation for being gentle on the skin. Research findings show that eczema patients experience better comfort and breathability when wearing lyocell instead of cotton. Tencel receives praise from apparel brands and reviews for its soft texture and hypoallergenic properties. One reviewer asserted that responsibly produced Tencel matches the safety standards of certified-organic clothing even though it isn’t organic. Both research and user feedback indicate Tencel has a gentle nature towards skin.

Environmental Impact vs. Toxicity

The minimal environmental impact of Tencel results in its non-toxic properties. The adoption of sustainable practices lowers the risk of environmental toxins spreading through the water, air, and soil.

Viscose and rayon are produced from wood pulp but they involve toxic carbon disulfide as part of their manufacturing process. The chemicals used in viscose and rayon production pose threats to both human workers and natural ecosystems.

The eco-friendly profile of Tencel fabric demonstrates how reducing environmental damage leads to decreased human harm. A clean manufacturing process produces fabric which is safer and cleaner for your skin.

Post-Production Treatments: Are They Toxic?

Chemical Finishes and Fabric Safety

Tencel fabric becomes dangerous when manufacturers apply hazardous dyes or finishes to it. Certain brands utilize wrinkle-resistant or anti-bacterial finishes which include formaldehyde and other harmful substances.

Importance of Organic Dyes

Choose Tencel clothing that uses organic or low-impact dyes to maintain safety standards. Verify fabric integrity by choosing products with GOTS certification to confirm that additional treatments remain safe.

GOTS-Certified Tencel

Tencel products with GOTS certification ensure no harmful treatments exist after production. Clothing that stays close to the skin like underwear and baby wear or bedsheets requires this consideration due to direct skin contact.

Choosing Safe Tencel Products

The following criteria help in identifying non-toxic Tencel.

- Check garments for the TENCEL™ trademark to authenticate their lyocell fiber composition.

- Select items with OEKO-TEX Standard 100 or GOTS or FSC certifications because they verify the absence of damaging chemicals.

- Select brands that use low-impact or OEKO-TEX approved dyes since non-toxic Tencel manufacturers usually display this information.

- Select finishes without chemicals and search for labels that specify “free of formaldehyde” or “PFC-free.”

- Review ethical brands’ sustainability reports and product descriptions to find their processing and safety standards information.

Debunking Myths

- Myth: Tencel fabric releases similar toxic residues as traditional rayon which is also known as viscose. Fact: Tencel production replaces carbon disulfide with the non-toxic NMMO chemical.

- The manufacturing process of Tencel allows for ~99% solvent recovery through its closed-loop system, so almost no toxins remain.

- Myth: Lyocell materials including Tencel exhibit the same synthetic and hazardous properties as polyester. Fact: Lyocell is mostly plant-based cellulose, not plastic. The production of Lenzing’s Tencel involves certified wood pulp and environmentally friendly processing which sets it apart from toxic rayon or plastic fibers.

- Myth: Tencel doesn’t qualify as organic material which means it could be considered unsafe. Fact: Tencel production operates under strict control even though it does not qualify as organic in agricultural terms. Proper manufacturing of Tencel results in safety levels equivalent to certified-organic clothing, Certification (OEKO-TEX/GOTS) ensures safety.

- Myth: Tencel off-gasses chemicals. Fact: The manufacturing process for Tencel includes washing and drying to eliminate solvents while ensuring that the material remains free of plasticizers. The tencel fabric does not emit toxic VOCs when maintained at regular room temperatures unlike polyester fibers. Tencel fabrics with certification meet all safety standards for volatile chemicals in garments.

- Myth: The dyes used for Tencel fabric always contain heavy metals. Fact: Multiple Tencel clothing items utilize dyes that have a reduced environmental impact or derive from plant sources. Selecting OEKO-TEX or GOTS-certified Tencel textiles guarantees the use of approved dyes without metals.

Conclusion-

Tencel (lyocell) presents minimal risk to human skin and environmental health. Through its closed-loop production method and non-toxic solvent use Tencel (lyocell) raw fiber remains free from harmful residues. The hypoallergenic properties of Tencel make it breathable fabric that usually does not trigger skin irritation. Dyes and finishes present the primary dangers but selecting Tencel products that have received OEKO-TEX or GOTS certification eliminates these threats. Properly produced and certified Tencel fabric provides a safe option for both human health and environmental protection. Shoppers can feel confident that “is Tencel fabric toxic” has been answered: Selecting appropriately ensures Tencel fabric remains both healthful and environmentally sustainable.

Read More>> About Modal Fabric Toxicity.

FAQs

Is Tencel Safe for Babies?

The extreme softness and gentle touch of Tencel makes it the ideal choice for baby clothing and bedding products. Tencel lacks irritants and allergens which leads many babywear brands to select it for their products.

Does Tencel Off-Gas Chemicals?

Tencel does not release toxic VOCs during use like various synthetic textiles do. The closed-loop process used in production guarantees near-total elimination of chemical residues.

Is Tencel Organic?

The GOTS certification for Tencel ensures it meets organic processing standards even though Tencel as a whole does not always possess organic properties. Always verify the label before purchasing.

Is Tencel Fabric Carcinogenic?

Research has not demonstrated that Tencel possesses carcinogenic properties. Under typical production conditions the NMMO solvent remains non-toxic and safe for use.