Introduction-

Polyester is among the most popular synthetic fabrics used throughout the world. Its pocket-friendly, moisture-resistant, and durable nature make it highly popular in clothing, home textiles, and industrial applications.

But what about the stretchability of polyester? This question is key when it comes to comfort-loving shoppers who desire freedom of movement in their clothing and other fabric products. This piece will cover everything. Shopping for activewear, day-to-day clothing, or durable upholstery? Then, understanding polyester before making the purchase is essential.

Let’s discover the fact “Is polyester fabric stretchy”. This article examines the stretchability of polyester and its blends and compares it with other fabrics.

The Origins of Polyester

Polyester was first made in the 1940s by British scientists John Rex Whinfield and James Tennant Dickson. They were associated with the Calico Printers’ Association in Manchester at that time. Whinfield and Dickson created a new polymer, a synthetic fiber that was capable of being spun into threads and woven into fabrics, named polyethylene terephthalate.

Polyester gained a lot of attention in the 50s after the DuPont company used it in fabrics, selling it in America under the brand Dacron. Its warmth, resistance to wrinkles, and ease of upkeep made it a staple in the American textile industry. Today, polyester is widely used in the production of clothes, home textiles, and other industrial products due to advancements in the technology used in its production.

Is Polyester Stretchy?

While polyester isn’t inherently stretchy, its stretchability does depend on how it’s woven and its blend with other fibers. 100% polyester is a stiff, tough fabric with almost no elasticity. The fabric contains purely polyester threads. It often comes in a woven fabric which is more stiff than knitted ones.

In its base form, polyester has very little elasticity, making it stiff and hard to stretch. But there are two critical ways in which manufacturers can improve the flexibility of polyester due to advancements in textile manufacturing technology:

Polyester Blends:

Polyester is much more stretchable when blended with elastic fibers like spandex or elastane, also called Lycra.

Some of the common blends are:

Polyester-Spandex Blend (e.g., 95% polyester, 5% spandex): This blend is stretchable enough to be used in activewear, leggings, and other form-fitting garments.

Polyester-Cotton-Spandex: It is made from polyester, cotton, and spandex, which makes it exceptionally durable and soft while providing elasticity.

Fabric Construction:

Knit Polyester: Knit polyester fabrics are comparatively more flexible and elastic than woven polyester fabrics.

Woven Polyester: Woven polyester has low elasticity but higher structure, which makes it suitable for formal clothing or household fabrics.

Different Types of Polyester

Polyester has following main types:

1. PET (Polyethylene Terephthalate) Polyester

- Description: The most common type of polyester, made from petroleum-derived polymers.

- Uses: Clothing, bottles, packaging, and industrial applications.

- Properties: Durable, lightweight, and resistant to wrinkles and shrinking.

2. PCDT Polyester

- Description: Less well-known than PET but well recognized for its elasticity and resistance to wear and tear.

- Uses: Used in stronger constructions such as upholstery, curtains, and even furniture pieces.

- Properties: It is more flexible and durable than PET, making it suitable for textiles needing extension.

3. Plant-Based Polyester

- Description: An eco-friendly substitute that is created from renewable resources such as corn or sugarcane.

- Uses: Environment-friendly textiles, clothing, and even packaging.

- Properties: Unlike regular polyester, it is biodegradable or recyclable, enhancing and lessening the effect on the environment.

4. Recycled Polyester (rPET)

- Description: The most common type of polyester, made from petroleum-derived polymers.

- Uses: Clothing, bottles, packaging, and industrial applications.

- Properties: Durable, lightweight, and resistant to wrinkles and shrinking.

5. Microfiber Polyester

- Description: Ultra-fine synthetic fibers, often blended with nylon.

- Uses: Cleaning cloths, athletic wear, and upholstery.

- Properties: Soft, lightweight, and highly absorbent.

6. High-Performance Polyester

- Description: Structured for particular functional features such as moisture-wicking, UV protection, or thermal insulation.

- Uses: Athletic clothing, outdoor equipment, and specialty fabrics.

- Properties: Improved durability, breathability, and environmental resistance.

7. Blended Polyester

- Polyester blended with fabrics like cotton, spandex, or wool.

- Common apparel such as regular wear, sportswear and home furnishing.

- Integrates the advantages of polyester like its durability and wrinkle resistance with the features of other fibers such as stretch from spandex or softness from cotton.

8. Filament Polyester

- Description: Made from long, continuous fibers.

- Uses: Smooth fabrics like satin, chiffon, and taffeta.

- Properties: Silky texture, lightweight, and lustrous appearance.

9. Staple Polyester

- Description: Made from short fibers spun together to create yarn.

- Uses: Fleece, blankets, and upholstery.

- Properties: Soft, warm, and fluffy texture.

10. Textured Polyester

- Description: Filament polyester that has been textured to add bulk and stretch.

- Uses: Knitwear, socks, and stretchy fabrics.

- Properties: Elastic, lightweight, and comfortable.

11. Water-Soluble Polyester

- Description: A temporary polyester variant that dissolves in water.

- Uses: Embroidery backing and medical applications.

- Properties: Dissolves completely, leaving no residue.

12. Flame-Retardant Polyester

- Description: Treated or engineered to resist burning.

- Uses: Protective clothing, curtains, and industrial applications.

- Properties: Self-extinguishing and meets safety standards.

13. Antimicrobial Polyester

- Description: Treated with antimicrobial agents to resist bacteria and odors.

- Uses: Sportswear, medical textiles, and socks.

- Properties: Hygienic, odor-resistant, and durable.

14. UV-Resistant Polyester

- Description: Treated to block harmful ultraviolet rays.

- Uses: Outdoor furniture, awnings, and sun-protective clothing.

- Properties: Prevents fading and degradation from sun exposure.

15. Biodegradable Polyester

- Description: Designed to break down naturally over time.

- Uses: Eco-friendly packaging and disposable textiles.

- Properties: Reduces environmental impact compared to traditional polyester.

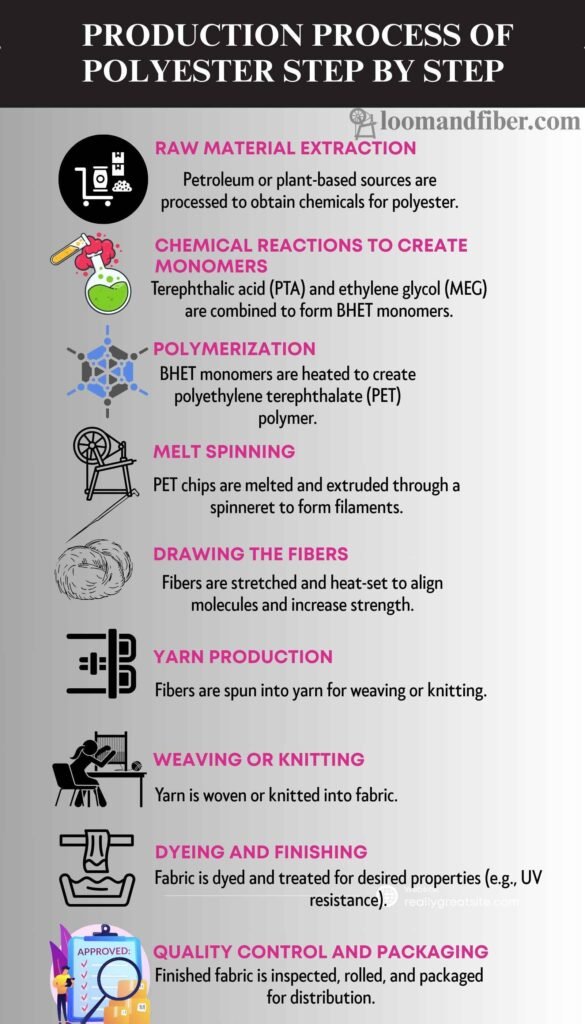

Production Process of Polyester step by step

1. Raw Material Extraction

Conventional polyester is obtained from petroleum, which is refined to get the required chemicals. As for more sustainable options, biomass such as maize or sugarcane can be utilized.

2. Chemical Reactions to Create Monomers

Purification of Terephthalic Acid (PTA) and Ethylene Glycol (MEG): Petroleum is refined to produce purified terephthalic acid (PTA) and ethylene glycol (MEG).

Esterification: Firstly, PTA and MEG are charged in a reactor to obtain a monomer known as bis(2-hydroxyethyl) terephthalate (BHET). This step requires heat, which is applied while extracting water that serves as one of the extracted sub products.

3. Polymerization

Polycondensation:

Through the use of heat and a vacuum, monomers of BHET can be fused together to create long-chain polymers such as polyethylene terephthalate. At this stage, methanol is separated from the mixture as it is no longer needed.

Result:

The next step of the process involves PET being extruded while liquid and then cooled. The final product, solid chips or pellets, is ideal as the base material for polyesters.

4. Melt Spinning

Pet Chips Melting: These PET chips are melted at high temperatures (260-270 degrees centigrade) to form a thick, viscous liquid.

Extrusion Formed Through The Spinneret: The molten polymers are forced through a spinneret (which is a device containing minute pores) to produce long thin filaments.

Cooling and Solidification: The filaments are cooled with air or water, solidifying into continuous fibers.

5. Drawing the Fibers

Stretching: Polymers are further strengthened and made more elastic through the stretching of solidified fibers to align polymer molecules.

Heat Setting: The fibers undergo heating to prevent shrinkage during further use, thus stabilizing their structure.

6. Texturizing (Optional)

Adding Texture:

For certain applications, the fibers are texturized to add bulk, softness, or stretch.

Methods:

False Twist Texturing: Adds crimp to the fibers for stretchiness.

Air Jet Texturing: Creates loops and curls for a softer feel.

7. Cutting into Staple Fibers (Optional)

For non-continuous fibers: If the polyester is intended for use in fabrics like fleece or stuffing, the continuous filaments are cut into shorter staple fibers.

For Blending: Staple fibers can be blended with other materials like cotton or wool.

8. Yarn Production

Spinning: The polyester fibers (either continuous filaments or staple fibers) are spun into yarn.

Twisting and Plying: Yarns can be twisted or plied to increase strength or create specific textures.

9. Weaving or Knitting

Fabric Formation: The yarn is woven or knitted into fabric.

Woven Polyester: Creates structured, less stretchy fabrics (e.g., for shirts, pants).

Knitted Polyester: Produces stretchy, flexible fabrics (e.g., for activewear, T-shirts).

10. Dyeing and Finishing

Dyeing: The fabric is dyed using disperse dyes, which bond well with polyester fibers.

Finishing: Additional treatments may be applied, such as:

Anti-static coating

Water repellency

Flame resistance

UV protection

11. Quality Control and Packaging

Inspection: The finished fabric is inspected for defects, strength, and color consistency.

Packaging: The fabric is rolled or folded, packaged, and shipped to manufacturers for use in clothing, home textiles, or industrial applications.

Environmental Considerations

Recycled Polyester (rPET):

For better environmental usage, it is possible to transform used plastic bottles or post-consumer polyester waste into polyester.

Eco-Friendly Alternatives:

New plant-based polyester and biodegradable polyester are on the rise as eco-friendly alternatives.

How Does Polyester Compare to Other Fabrics?

Polyester vs. Cotton

| Properties | Polyester | Cotton |

| Durability | Very strong and long-lasting. | Less durable than polyester and prone to pilling and tearing. |

| Stretchiness | Not stretchy unless mixed with spandex. | Not stretchy unless blended with spandex. |

| Comfort | Feels hot and can feel synthetic. | Soft, breathable, and comfortable for everyday wear. |

| Moisture-Wicking | Great at moisture-wicking. | Absorbs moisture but retains it, leading to a damp feeling. |

| Care | Wrinkle-free, easy to wash, and dries fast. | Prone to wrinkling and shrinking, requires more maintenance. |

| Environmental Impact | Not compostable but can be recycled. | Biodegradable but requires significant water and pesticides to grow. |

Polyester vs. Wool

| Properties | Polyester | Wool |

| Durability | Very strong and long-lasting. | Durable but can be prone to pilling and moth damage. |

| Stretchiness | Not stretchy unless mixed with spandex. | Naturally elastic and retains shape well. |

| Comfort | Feels hot and can feel synthetic. | Warm, breathable, and soft, it is ideal for cold weather. |

| Moisture-Wicking | Great at moisture-wicking. | Absorbs moisture while remaining warm. |

| Care | Wrinkle-free, easy to wash, and dries fast. | It requires special care, is often dry-clean only, and is prone to shrinking. |

| Environmental Impact | Not compostable but can be recycled. | Biodegradable and renewable but involves animal farming. |

Polyester vs. Nylon

| Properties | Polyester | Nylon |

| Durability | Very strong and long-lasting. | Highly durable and tear resistant. |

| Stretchiness | Not stretchy unless mixed with spandex. | Easier to stretch than polyester. |

| Comfort | Feels hot and can feel synthetic. | Light and soft but has low breathability. |

| Moisture-Wicking | Great at moisture-wicking. | Retains smells while wicking moisture away. |

| Care | Wrinkle-free, easy to wash, and dries fast. | Wrinkle-resistant, quick-drying, and low maintenance. |

| Environmental Impact | Not compostable but can be recycled. | Difficult to recycle and consumes a lot of energy to manufacture. |

Polyester vs. Spandex (Lycra/Elastane)

| Properties | Polyester | Spandex |

| Durability | Very strong and long-lasting. | Not as strong as polyester, can lose elastic stretch with age. |

| Stretchiness | Not stretchy unless mixed with spandex. | Super elastic, can extend 5-8 times original length. |

| Comfort | Feels hot and can feel synthetic. | Of lightweight construction, form-fitting but not aerated. |

| Moisture-Wicking | Great at moisture-wicking. | Excellent moisture wicking capabilities. |

| Care | Wrinkle-free, easy to wash, and dries fast. | Gentle care is required; high temperatures will ruin elastic elongation. |

| Environmental Impact | Not compostable but can be recycled. | Made from Non-biodegradable and Petroleum products. |

Polyester vs. Silk

| Properties | Polyester | Silk |

| Durability | Very strong and long-lasting. | Less strong, easily snags and rips. |

| Stretchiness | Not stretchy unless mixed with spandex. | Slightly elastic but not stretchy. |

| Comfort | Feels hot and can feel synthetic. | Gently soothing, well-ventilated, and allergy friendly. |

| Moisture-Wicking | Great at moisture-wicking. | Soaks up moisture while staying dry and comfy. |

| Care | Wrinkle-free, easy to wash, and dries fast. | Tender care is needed. Most of the time dry-clean only, and easily gets water stains. |

| Environmental Impact | Not compostable but can be recycled. | It will decompose but requires the farming of silkworms. |

What Are Polyester Blends?

Polyester blends are made from polyester and are combined with either natural or synthetic fibers. These blends aim to enhance the fabric’s performance, feel, versatility, and overall functionality.

Polyester-Spandex (Elastane/Lycra) Blend

Composition: Usually 95% polyester and 5% spandex.

Stretchability- High stretch and elastic recovery.

Uses- Activewear, leggings, bathing suits, and other tight clothing.

Benefits- Great stretch and increased recovery. Shape retention. Wrinkle free and long-lasting.

Polyester-Cotton Blend

Composition: Usually a blend of 65% polyester and 35% cotton (or other ratios).

Stretchability: Has little stretchability without spandex.

Uses: T-Shirts, bedsheets, and other informal clothing.

Benefits:

Provides comfort with extra durable material.

Breathable and comfortable

Convenient cleaning.

Polyester-Rayon Blend

Composition and Uses: Shift dresses, blouses, and other casual wear is made of polyester and rayon fabric which usually has a composition of about 50% polyester and 50% rayon.

Stretchability: This fabric blend has a lower elasticity, but it does stretch somewhat.

Benefits: Its Benefits Soft and smooth touch, flows excellently, and is inexpensive and flexible in usage.

Polyester-Wool Blend

Composition: Differs, frequently 55% polyester + 45% wool.

Elongation: moderate elongation because of the elasticity of the wool.

Applications: Designed for suits, coats, and other outerwear.

Benefits:

Blends the softness of wool and the strength of polyester.

Supple to creases and shrinkage.

Less difficult to maintain than 100% wool.

Polyester-Nylon Blend

Composition: Usually, 85% polyester and 15% nylon, but can differ.

Stretchability: Stretchable to a moderate degree, depending on the blend.

Uses: Used in outdoor fabric, swimsuits, and performance textiles.

Benefits:

In comparison to other materials, the strength and resistance to abrasive damage is phenomenal.

Very lightweight. Dries rapidly.

Great for cutting-edge applications.

Polyester-Acrylic Blend

Composition: Usually, the make or break of an item is 50% polyester and 50% acrylic.

Stretchability: Stretching ability is low.

Uses: Fleece, blankets, and knitwear.

Benefits: Soft and warm. Resistant to pilling and fading. Economically represents wool.

Applications of Stretchy Polyester Blends

Activewear

Polyester-spandex blends are perfect for yoga pants, sports bras, and running shorts due to their stretch and moisture-wicking properties.

Swimwear:

The elasticity and durability of polyester-spandex blends make them ideal for swimsuits.

Casual Wear:

Polyester-cotton blends are utilized in the production of T-shirts, jeans, and other casual wear because of their convenience and durability.

Formal Wear:

Polyester blended with wool is incorporated into blazers and suits to provide shape, but also allow for movement.

Outdoor Gear:

Strength and protection to the weather are the main reasons polyester-nylon blends are utilized in jackets, backpacks, and tents.

Pros and Cons of Polyester

Pros

Durability – Rugged and tough, and do not easily get damaged.

Wrinkle Resistance – Retains original shape regardless of the number of washes.

Moisture Wicking – Keeps the user dry and comfortable by pulling the sweat away.

Affordable – Natural fibers have a higher price, hence, we consider these affordable.

Shape Retention – Stretchy blends do not sag; hence, they keep the form perfectly.

Cons

Less Breathable – Can restrict movement of air causing discomfort at high temperatures.

Odor Retention – Absorbs smell of sweat and thus, needs to be washed more frequently.

Environmental Concerns – Contributes to pollution through the microplastics that it produces.

Static Build-Up – Lint and dust are attracted to it easily, particularly when the weather is dry.

How to Care for Stretchy Polyester Fabrics

Washing Tips

- Use cold water to prevent shrinkage

- Turn garments inside out to protect prints

Drying Tips

- Avoid high heat in dryers

- Air-dry for best results

General Maintenance

- Use mild detergents

- Avoid harsh chemicals like bleach

Conclusion-

So, is polyester stretchable? Lack of stretch in pure polyester is common, but a blend of polyester offers fantastic stretch. Stretchy polyester is suitable for sports and casual wear and even for home fabrics since it is comfortable, durable, and does not wrinkle.

Choosing the right blend guarantees you stretch, breathability, and even adequate life span for your clothes. If taken care of and used responsibly, polyester can be practical and sustainable. Read More >> satin Fabric, Muslin Fabric.

FAQs

Is 100% polyester stretchy?

No, pure polyester is rigid. It becomes stretchy when blended with spandex or elastane.

Does polyester shrink when washed?

Polyester resists shrinkage but may slightly tighten in high heat. Washing in cold water helps maintain its shape.

Can polyester be used for sportswear?

That 100% Yes! Stretchy polyester blends like polyester-spandex are used in sportswear because of their flexibility and moisture management.

Is polyester good for hot weather?

It depends on the fabric weave. Lightweight polyester blends are suitable for summer, but thick polyester can trap heat.

[…] Is Polyester Stretchy? A Complete Guide to Its Flexibility […]

[…] Is Polyester Stretchy? A Complete Guide to Its Flexibility […]

[…] Is Polyester Stretchy? A Complete Guide to Its Flexibility […]

[…] Is Polyester Stretchy? A Complete Guide to Its Flexibility […]

[…] Polyester is a long-lasting, smooth-to-clean fabric commonly used for hospital curtains. It resists stains and wrinkles, making it a practical option for healthcare environments. […]

[…] Polyester is another common choice for sheer curtains as it’s a synthetic fabric that offers lots of versatility. It replicates the softness of natural textiles but is cost-effective and easy to care for. […]

[…] Polyester curtains may be less costly than linen curtains but they are not as breathable and environmental friendly as linen. Linen’s natural fibers are less damaging to indoor air quality and less terrible to the environment compared to microfiber. […]

[…] seersucker fabric has been made of 100 percent cotton. Current styles now include blends of polyester, elastane, and even linen. These fabrics add elasticity, durability, and lowered shrinkage, while […]

I found the section on polyester blends really interesting, especially how combining polyester with other fabrics can affect its stretch and durability. It’s amazing how the right combination can provide both flexibility and strength in different products.

The way you connected the production process to the fabric’s final properties was really insightful. It made me realize how much fiber construction and processing methods actually influence how stretchy polyester can be.

[…] and polyester are both common in activewear, but they behave differently when wet. At equal thickness, polyester […]