You’re running the machine, everything looks “mostly fine,” and then it happens: wrinkles, ridges, or a wavy “not-laying-flat” forming fabric starts showing up. Your sheet formation gets moody, drainage becomes unpredictable, and you can almost hear the downstream breaks and quality complaints lining up.

The frustrating part is that wrinkles and ridges often feel random. They’re not. In most cases, they come from a small set of repeatable causes: uneven tension, misalignment, contamination (plugging), unstable rolls/vacuum elements, or “invisible” water/shower issues that slowly push the fabric into bad behavior.

This article gives you exactly what the title promises: five easy, practical solutions you can apply without turning the problem into a week-long engineering project. You’ll also get quick checks, simple numbers, and real-life scenarios so you can act fast—and know you actually fixed it.

First, a quick, everyday definition (so you don’t chase the wrong problem)

Wrinkles are localized folds or creases in the forming fabric. Think “shirt wrinkle”: it’s a bend that shouldn’t be there. On a machine, wrinkles can come and go, but even a short-lived wrinkle can mark the sheet or trigger instability.

Ridges are longer, more “structural” raised lines or waviness across or along the fabric. Think “carpet ripple”: it lays down wrong and stays wrong until you change the conditions.

Waviness / not laying flat is the broader symptom. The fabric might look like it’s gently rolling or “breathing.” It’s a warning sign, because waviness often becomes wrinkles under load or at higher speeds. A practical reference that explains why flatness matters (and lists common causes) is this forming-fabric flatness guide: Feltest “5 tips for forming fabrics that will not lay flat” (you’ll find plain-language causes like tension, guiding, and fabric handling).

Before you touch anything: a 3-minute “stop guessing” checklist

Use this mini-check so you don’t waste time adjusting the wrong knob.

- Where do you first see it? Near a particular roll/box/foil, or only after a shower? The first location is a huge clue.

- Is it edge-driven or center-driven? Edge wrinkles often point to guiding, edge wear, edge contamination, or uneven showers. Center ridges often point to tension profile, vacuum element issues, or cross-machine contamination.

- Does it change with speed or vacuum? If it gets worse when speed increases or vacuum changes, you’re likely dealing with stability/air-water balance, box loading, or a tension/vacuum interaction.

- Is the fabric clean and draining? Contamination reduces permeability, changes drainage forces, and can “steer” the fabric into ridges and wrinkles over time. Industry sources repeatedly emphasize that fabric cleanliness is critical for stable dewatering and runnability, not just sheet quality. TAPPI Paper360: Best Practices for Cleaning Forming Fabrics and Press Felts.

Quick visual cues (so you can explain it to someone in 30 seconds)

Table 1: Fast diagnosis map (symptom → likely cause → what you check first)

| What you see | Most likely driver | First check (fast) | What “good” looks like |

| Edge wrinkles that come and go | Guiding sensitivity, edge showers, edge contamination | Guide response + edge cleanliness | Stable edge tracking with no sudden guide corrections |

| Long ridges across width | Cross-machine tension profile or uneven vacuum/boxes | Tension readings across width + element loading | Even tension and no “hot spots” of suction/drag |

| Wrinkle appears after showers | Plugged nozzles, uneven water distribution, wrong oscillation | Nozzle pattern + oscillation + pressure stability | Uniform wetting/cleaning across the full width |

| Wrinkle near one roll/box | Roll condition (vibration), box edge, alignment, local drag | Roll runout/vibration + box surface/edge condition | Quiet, steady run with consistent contact |

Two simple formulas that help you decide “how urgent is this?”

Formula 1: Downtime cost (so you can justify quick action)

Downtime Cost = Hours Lost × Cost per Hour

Example you can actually use: if an instability forces you to slow down and lose 1.5 hours of production time this week, and your site estimates downtime at about $20,000 per hour, then:

Downtime Cost = 1.5 × $20,000 = $30,000

That $20,000/hour reference is commonly cited for pulp and paper machinery downtime in a Siemens industry paper. Siemens: Predictive maintenance for pulp and paper mills.

And if you want a very recent, mainstream snapshot of how expensive downtime can get in manufacturing, this October 2025 coverage summarizes research and reported impacts (it’s broader manufacturing, but it’s a useful “executive-language” reference): ITPro (Oct 2025): downtime losses research summary.

Formula 2: Tension spread (so you can spot “hidden” unevenness)

Tension Spread (%) = (Max Tension − Min Tension) ÷ Target Tension × 100

Example: you measure across the width and get 6.0 kN/m max and 5.4 kN/m min, and your target is 5.7 kN/m:

Tension Spread = (6.0 − 5.4) ÷ 5.7 × 100 ≈ 10.5%

In plain terms: a ~10% spread is often enough to encourage ridges/waviness, especially when combined with vacuum and water forces. The exact “acceptable” spread depends on your machine and fabric design, but this simple percent gives you a consistent way to compare “today vs yesterday” and confirm improvement after adjustments.

If you don’t have a reliable way to measure running tension, handheld web tension meters exist specifically for forming fabrics, sieves, and felts. A practical example (with specs and operating ranges) is the Checkline 136-2: Checkline 136-2 Hand-Held Tension Meter.

Table 2: The five solutions at a glance (what you do, how long it takes, how you know it worked)

| Solution | Typical time to try | Main tool(s) | Success signal |

| 1) Re-balance tension | 10–30 minutes | Tension gauge + notes | Ridges relax, fabric looks “quiet” |

| 2) Fix guiding/alignment | 15–45 minutes | Guide observation + alignment checks | Stable tracking, fewer guide corrections |

| 3) Restore drainage with smarter cleaning | 30–90 minutes | Showers + nozzle inspection | Even wetting, improved release and dewatering |

| 4) Remove “local drag” from rolls/boxes | 30–120 minutes | Vibration/listen-check + surface inspection | Wrinkle disappears at the same location |

| 5) Lock in stability with a simple monitoring habit | 5 minutes per shift | Checklist + trend notes | Fewer repeats, faster root-cause detection |

Solution 1 (Easy): Re-balance forming fabric tension so the fabric stops “buckling”

If wrinkles and ridges had a “most common” trigger, it would be tension that is either too low overall or uneven across the width/front-to-back. Low or uneven tension lets the fabric behave like a loose bedsheet: it can’t resist the forces of water removal, vacuum, and roll contact, so it starts to form waves—and waves eventually become wrinkles.

What you do (simple, step-by-step):

- Measure before you touch anything. Take tension readings at multiple points (drive side, center, tending side; and if possible, in more than one location around the loop). Record them.

- Calculate your tension spread. Use the formula above. You’re not hunting perfection; you’re hunting “less uneven than before.”

- Make small adjustments. Tiny changes matter. Adjust, then re-measure after the fabric stabilizes (don’t trust the first 30 seconds).

- Watch the fabric, not just the numbers. A good result looks calmer: fewer ripples, less “breathing,” and a more consistent run.

- Confirm with a runnability sign. For example: fewer sudden guide movements, improved sheet stability, fewer edge flutter signs.

Everyday scenario: You tighten a backpack strap. If one side is looser, the bag pulls crooked and rubs your shoulder. A forming fabric does the same thing: uneven tension makes it “pull” toward the tighter side and wrinkle where it can’t smoothly distribute the load.

Common confusion #1: “If I increase tension, won’t I just cause more wear?” You can, if you overshoot. The goal is correct tension and balance, not “as tight as possible.” The better mindset is: “Enough tension to stay flat, evenly distributed, and stable under the machine’s normal vacuum and water load.”

Mistake story (relatable): You’re in a rush, you adjust tension based on a single reading near the drive side, and you feel proud because the number looks “right.” Two hours later, the ridges are worse—because the center and tending side were still low, and the fabric effectively became a twisted sheet under load. The fix wasn’t “more tension,” it was balanced tension.

Helpful resource: A tension meter built for running forming fabrics (wet or dry) can reduce guesswork. The Checkline 136-2 product page shows ranges and measurement use-cases that match forming fabrics and felts. Checkline 136-2 tension meter.

Key takeaway: If you do only one thing first, do this: measure across width, calculate spread, adjust gradually, re-measure. It’s the fastest path from “mystery wrinkles” to “predictable stability.”

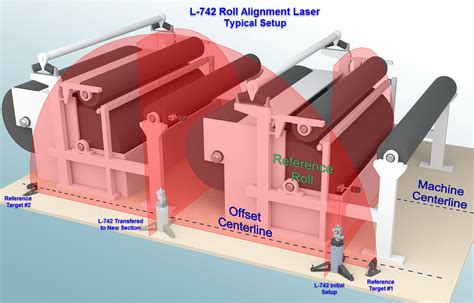

Solution 2 (Easy): Fix guiding and alignment so the fabric stops “steering itself” into trouble

A fabric that doesn’t track steadily will fight you. Small tracking errors create edge stress, and edge stress becomes edge wrinkles. Even worse: constant guide corrections can add tiny cyclic forces that show up as repeating ridges.

Recent practitioner-focused guidance highlights that guiding and alignment issues can quickly spiral into downtime and inconsistent formation if you don’t address the contributing factors early. PMC Centre: Tackling guiding and alignment challenges (recent post).

What you do (simple, step-by-step):

- Observe guide behavior for one full cycle. Is it smooth and minimal, or twitchy and over-correcting? Over-correction often creates edge stress.

- Check wrap and lead-in/lead-out geometry. Poor wrap or awkward lead-in can reduce guiding effectiveness and cause hunting (constant correction back and forth).

- Check for “uneven pull.” Uneven tension (Solution 1) can masquerade as guiding trouble—so if you skipped Solution 1, you’re now guessing again.

- Inspect edge condition. Edge contamination, edge damage, or uneven edge showers can make one side behave like it has a different friction level, which steers the fabric.

- Make one change at a time. Change, observe, and document. If you change three things, you won’t know what worked.

Everyday scenario: If your shopping cart has one sticky wheel, it keeps drifting toward one side. You can “guide” it, but you’re constantly correcting. A forming fabric behaves similarly when one edge has more drag, tension, or contamination.

Mistake story (relatable): You see the fabric drifting and immediately adjust the guide sensitivity upward because “it needs to respond faster.” The fabric stops drifting—but now the guide is overactive and you create a repeating edge wrinkle every time the guide snaps. The better fix would have been to remove the underlying cause (edge drag, tension spread, or misalignment) before making the guide more aggressive.

Helpful resource: A classic troubleshooting reference that lists guiding-related areas to consider (vacuum, sensitivity, tension, wrap, bearings, etc.) is the AstenJohnson troubleshooting chapter PDF: AstenJohnson: Paper Machine Troubleshooting..

Key takeaway: A well-guided fabric looks boring. That’s your goal. If you see frequent guide “hunting,” treat it as a symptom, not the root cause.

Solution 3 (Easy): Restore drainage and flatness by cleaning smarter (not just “more water”)

Contamination is sneaky. It builds slowly, changes permeability, and makes the fabric drain unevenly. Uneven drainage creates uneven forces; uneven forces create ridges and wrinkles. You might think you’re fighting a mechanical issue when you’re actually fighting a “plugged fabric” issue.

Industry guidance aimed at operators emphasizes that maintaining fabric void volume and cleanliness is core to runnability. Kadant’s forming-fabric cleaning guidance describes high-pressure cleaning showers (including typical placement distance and purpose) and explains how cleaning systems reduce contaminants that contribute to downtime. Kadant: Cleaning and Conditioning Forming and Press Section.

What you do (simple, step-by-step):

- Inspect nozzles and patterns. Plugged or partially plugged nozzles create uneven cleaning, which creates uneven drainage—and that can show up as ridges.

- Confirm oscillation is working correctly. A “stuck” oscillator can over-clean one band and under-clean another, creating a cross-machine drainage mismatch.

- Use the right intensity at the right time. High-pressure cleaning is often best run intermittently as needed (rather than blindly maxing it), depending on your system and fabric. Kadant’s documentation describes typical high-pressure cleaning purpose and configuration for maintaining fabric cleanliness.

- Check edges separately. Edges often need different attention (trim, deckle, edge shower patterns). Edge contamination is a frequent wrinkle trigger.

- Validate by looking for “even behavior.” You’re looking for more uniform wetting/cleaning and a calmer fabric run—not just “it looks wet.”

Everyday scenario: Imagine washing a window but your spray bottle is clogged on one side. You keep scrubbing harder, but the streaks stay—because the problem is uneven spray, not “lack of effort.” With forming fabrics, uneven cleaning is the streak-maker.

Common confusion #2: “If contamination causes ridges, why do I sometimes see ridges right after cleaning?” Because cleaning can temporarily change local friction and water loading. If the cleaning is uneven (plugged nozzles, bad oscillation, uneven pressure), you can briefly make the force imbalance worse. That’s not a reason to avoid cleaning; it’s a reason to clean uniformly.

Mistake story (relatable): You bump shower pressure up because the fabric “looks dirty,” but you don’t check nozzle condition. A week later, you’re convinced the fabric is defective—when the real issue is that half the nozzles were partially blocked and you created a persistent cross-machine ridge pattern.

Helpful resources (practical links you can use):

- TAPPI Paper360 cleaning best practices (operator-friendly explanation of why cleanliness matters for permeability and dewatering).

- Kadant cleaning/conditioning guide (equipment-focused guidance on shower purpose, positioning, and cleaning systems).

Key takeaway: Don’t treat showers like a volume knob you turn up forever. Treat them like a precision tool: uniformity first, then intensity.

Solution 4 (Easy): Remove “local drag” from rolls, boxes, and elements where the wrinkle starts

If the wrinkle or ridge consistently appears at (or right after) a specific roll, suction box, foil, or table element, you may be dealing with local drag, vibration, wear, or a surface condition that “grabs” the fabric unevenly. This is especially common when something is slightly misaligned or when a component is worn just enough to create a repeating force pattern.

Troubleshooting references for the forming section often point to roll condition, vibration, seals, bearing housings, and comparison of sheet mark to fabric pattern as useful checks when runnability symptoms show up. AstenJohnson troubleshooting chapter PDF.

What you do (simple, step-by-step):

- Mark the location. If you can safely do so under your site procedures, identify the “first appearance point.” That’s your investigation anchor.

- Listen and feel (carefully, safely). Vibration and unusual noise often correlate with a roll/bearing issue that creates periodic fabric disturbance.

- Check surfaces and edges. A sharp edge, a worn cover, or a damaged box surface can create a localized snag or friction change.

- Look for repeating frequency. If the wrinkle pulses in a repeating rhythm, it may match roll rotation or an oscillation cycle.

- Confirm with a small operational change. If safe and allowed: slight speed change or vacuum adjustment to see whether the symptom shifts. Shifts often indicate a dynamic interaction rather than a static fabric defect.

Everyday scenario: A washing machine with an unbalanced drum doesn’t just “shake sometimes.” It shakes in a repeating pattern that gets worse at certain speeds. Your forming section can behave the same way when a roll is slightly off, a bearing is loose, or an element adds periodic drag.

Common confusion #3: “But the fabric looks fine when we inspect it offline.” Many local-drag problems only show up under operating load (vacuum, water, speed). Offline inspection is still useful, but don’t let it talk you out of the obvious: if the wrinkle starts at one location, treat that location as guilty until proven otherwise.

Mistake story (relatable): The wrinkle always appears after one suction box. You replace the fabric because it’s the easiest “big move.” The new fabric wrinkles too. Now you’ve paid for a fabric you didn’t need and still have the same root cause—often a box surface/edge condition, a vacuum imbalance, or a mechanical alignment issue.

Key takeaway: When a wrinkle has a consistent “birthplace,” stop debating and investigate that birthplace. Local drag problems rarely fix themselves.

Solution 5 (Easy): Lock in stability with a tiny monitoring habit (so the problem doesn’t keep coming back)

Here’s the uncomfortable truth: you can fix wrinkles and ridges today and still see them again next week if you don’t capture the conditions that caused them. The best long-term “easy solution” is a small, repeatable routine that catches drift early—before it becomes visible ridges.

This is also where you can borrow a simple idea from predictive maintenance: trend the variables that matter, and you’ll stop being surprised. In pulp and paper contexts, industry materials commonly emphasize that unplanned downtime is expensive and that condition-based/predictive approaches can improve availability and maintenance effectiveness. For example, Siemens discusses high downtime costs and potential downtime reduction benefits from predictive maintenance in pulp and paper environments.

And for a very recent (December 2025) example of industrial-AI framing in paper plants, this white paper reports metrics like machine availability and reductions in MTTR in the paper-plant context (treat it as vendor-provided, but the timeliness is useful for “what’s current” in maintenance thinking): MOVUS (Dec 2025) AI-driven predictive maintenance for paper plants.

What you do (simple, step-by-step):

- Create a one-page “fabric flatness log.” Three numbers and two observations per shift is enough.

- Track these three numbers:

- Tension (DS/Center/TS) and your tension spread (%)

- Vacuum level at key boxes (just the ones most tied to your symptom location)

- Shower pressure (or cleaning cycle setting) for the showers most related to your fabric cleanliness

- Track two observations:

- Guide behavior (stable / hunting / frequent corrections)

- Visible fabric behavior (quiet / wavy / ridge lines / edge flutter)

- Set one simple “early warning rule.” For example: “If tension spread exceeds 8–10% for two shifts in a row, we re-balance tension before ridges appear.” (Pick your number based on your machine’s history.)

- Make the log easy to find. If it’s buried, it won’t happen. Put it where shift handover happens.

Everyday scenario: If you only check your car’s tire pressure when the tire looks flat, you’ll end up stranded. If you check it weekly, you catch slow leaks early. Your fabric behaves the same way: drift happens before symptoms show up.

Safety note you should not skip: If your checks require maintenance interaction with energized equipment, follow your facility’s lockout/tagout program. The OSHA hazardous energy control standard (29 CFR 1910.147) is the baseline reference in the U.S. and clearly defines responsibilities and required practices. OSHA eCFR: 29 CFR 1910.147.

Key takeaway: The easiest long-term fix is not a heroic repair; it’s a small habit that stops “drift” from becoming “damage.”

Table 3: What the five solutions look like in everyday mill situations (and how much trouble they can prevent)

| Everyday situation | Most effective solution | What you prevent | Simple “win” metric |

| Wrinkles show up after a grade change | 1 + 3 (tension + cleaning uniformity) | Chasing settings for hours | Wrinkles gone within 1–2 adjustments |

| Edge wrinkles during speed-up | 2 (guiding/alignment) plus check edge condition | Edge breaks and sheet edge defects | Guide corrections reduced (less hunting) |

| Ridges that slowly worsen over days | 3 + 5 (cleaning + monitoring) | Permeability loss, unstable drainage | Stable tension spread and calmer run |

| Wrinkle always starts at one box/roll | 4 (local drag investigation) | Repeated fabric marking and recurring defects | No wrinkle at that location after intervention |

Six practical external links (what you’ll find, and why they help)

- Feltest: forming fabrics not laying flat — a practical, operator-focused list of common causes and quick tips for fabric flatness and waviness.

- AstenJohnson: Paper Machine Troubleshooting (PDF) — a structured troubleshooting guide that helps you map symptoms to likely mechanical/process areas in the forming section.

- Kadant: Cleaning and Conditioning Forming and Press Section — detailed guidance on shower purpose, positioning, and cleaning approaches that protect fabric void volume and runnability.

- TAPPI Paper360: Cleaning best practices — an accessible explanation of how cleanliness supports permeability, dewatering, and productivity, with practical context for operators.

- OSHA eCFR: 29 CFR 1910.147 — the official lockout/tagout standard reference, useful for staying compliant when troubleshooting requires maintenance actions.

- ITPro (Oct 2025): Downtime losses research summary — a recent, mainstream summary that helps you communicate downtime urgency and justify proactive fixes and monitoring.

Putting it all together: a simple “do this in order” playbook

If you’re standing on the floor right now and want a clean sequence that avoids ping-pong troubleshooting, do this:

- Start with tension balance (Solution 1). Measure, compute spread, adjust gradually.

- Watch guiding behavior (Solution 2). Reduce hunting, check edges, fix underlying drift drivers.

- Confirm cleaning uniformity (Solution 3). Nozzles, oscillation, even wetting/cleaning across width.

- If the wrinkle has a “birthplace,” go there (Solution 4). Rolls/boxes/elements for local drag, vibration, wear.

- Prevent the repeat (Solution 5). Log three numbers, two observations, and act on early warnings.

You’ll notice something reassuring: these five solutions are not exotic. They’re the same few levers that most forming-fabric flatness problems come back to. The difference is doing them in a calm order, with simple measurements and clear success signals.

Conclusion: Your five easy solutions, summarized in one breath

When your forming fabric shows wrinkles or ridges, you don’t need a mystery hunt. You need five dependable moves: (1) balance tension, (2) stabilize guiding and alignment, (3) clean uniformly to restore drainage, (4) eliminate local drag where the wrinkle starts, and (5) keep a tiny shift-by-shift log so drift never surprises you again.

Once you see even a 50% improvement in visible waviness or ridge intensity, don’t stop—lock it in. Keep the monitoring habit for two weeks, compare your tension spread trend, and you’ll usually find the problem becomes predictable, then preventable.

If you want one final mindset that keeps this easy: wrinkles and ridges are rarely “random fabric behavior.” They’re your machine giving you feedback. Listen early, adjust simply, and your fabric will lay flat like it’s supposed to.

I got this site from my friend who told me about this web

page and at the moment this time I am browsing this site and reading very informative articles here.

Oh my goodness! Impressive article dude! Many thanks, However I

am having problems with your RSS. I don’t understand why I am unable

to join it. Is there anybody having similar RSS problems? Anyone that knows the solution will you kindly

respond? Thanks!!

Appreciating the persistence you put into your website and detailed information you

offer. It’s nice to come across a blog every once in a while that isn’t the same

out of date rehashed material. Great read! I’ve saved

your site and I’m adding your RSS feeds to my Google account.