Introduction-

Viscose also called “Rayon” is a semi-synthetic textile that finds application across fashion, upholstery, and industrial usage. It has a rather soft texture, possesses a shine similar to silk and is breathable. Most people know it by the name rayon and because of its appealing look, it is also called ‘artificial silk’ sometimes.

Rayon was first made to be a cheaper substitute for silk. It is made from wood pulp; usually beech, pine or eucalyptus trees. The production process requires series of chemical processes that changes natural cellulose into a fiber that can be used as a fabric. Therefore, it sits in the middle of natural and synthetic fibers, which classifies it as semi-synthetic textile.

Although viscose is largely used, it is debated in regards to sustainability due to the considerable amount of chemicals used in its production. Nevertheless, innovations like eco-friendly lyocell and bamboo Rayon are some improvements made towards making the fabric more sustainable.

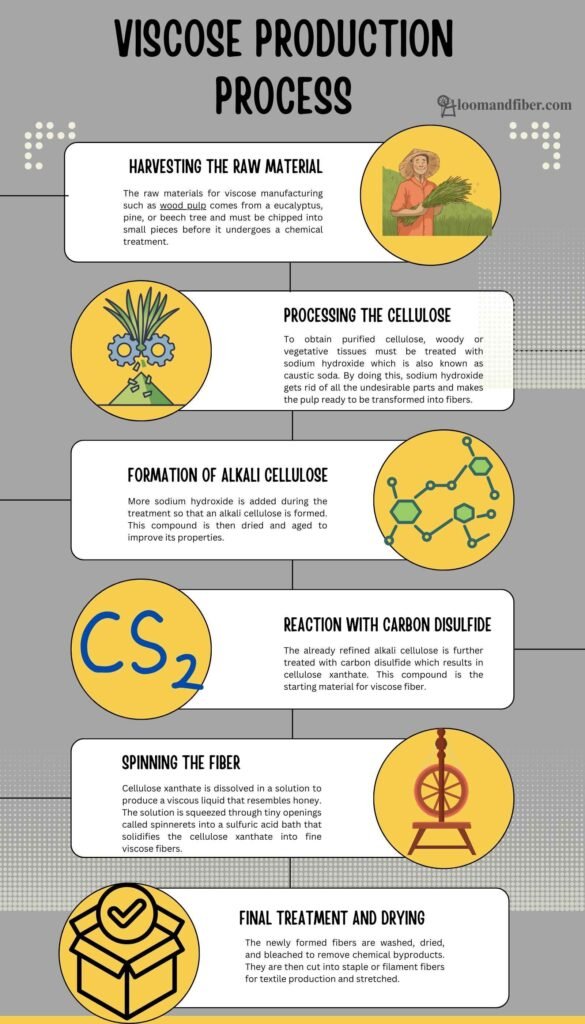

How Viscose is Made

Getting viscose involves a complicated set of chemical processes which use wood pulp by converting it into fine fibers. Here’s a summary of the steps:

Harvesting the Raw Material

The raw materials for viscose manufacturing such as wood pulp comes from a eucalyptus, pine, or beech tree and must be chipped into small pieces before it undergoes a chemical treatment.

Processing the Cellulose

To obtain purified cellulose, woody or vegetative tissues must be treated with sodium hydroxide which is also known as caustic soda. By doing this, sodium hydroxide gets rid of all the undesirable parts and makes the pulp ready to be transformed into fibers.

Formation of Alkali Cellulose

More sodium hydroxide is added during the treatment so that an alkali cellulose is formed. This compound is then dried and aged to improve its properties.

Reaction with Carbon Disulfide

The already refined alkali cellulose is further treated with carbon disulfide which results in cellulose xanthate. This compound is the starting material for viscose fiber.

Spinning the Fiber

Cellulose xanthate is dissolved in a solution to produce a viscous liquid that resembles honey. The solution is squeezed through tiny openings called spinnerets into a sulfuric acid bath that solidifies the cellulose xanthate into fine rayon fibers.

Final Treatment and Drying

The newly formed fibers are washed, dried, and bleached to remove chemical byproducts. They are then cut into staple or filament fibers for textile production and stretched.

Viscose/Rayon Production Process

Viscose/Rayon Production ProcessProperties of Viscose

Viscose possesses unique characteristics that make it popular in textiles.

Softness and Silk-Like Feel

The primary reason garment manufacturers favor rayon is its smooth, silky texture. It is comfortable to wear and enhances one’s beauty.

Breathability and Moisture Absorption

It is used for summer clothing because viscose is very breathable and can retain moisture from the body. It helps keep the body dry and lets air pass through which is refreshing.

Drapability and Versatility

Viscose is commonly used for dresses and skirts. The fluid-like nature of viscose makes it easy to create flowing garments. It fits to the body’s shape which give off an attractive outline.

Uses of Viscose

Viscose is widely used across multiple industries.

Clothing

A must have in any closet’s wardrobe, it is present in blouses, dresses, skirts, and linings. Its thickness is perfect for stylish yet budget friendly garments, which make it popular among the masses.

Home Textiles

Viscose’s use extends to bed sheets, curtains, and even upholstery fabrics because of its soft touch and aesthetic appeal. It completes the elegant touch of a home decor.

Industrial Applications

Viscose fabrics, in addition to being popular in garments, home textiles and curtains, are also used in the production of medical textiles, tire cords, and even disposable wipes because they are absorbent and biodegradable.

Pros and Cons of Viscose

Advantages

- Low-cost substitute for silk – Feels great while costing less than the original.

- Biodegradable – rayon dissolves faster in nature than fully synthetic fibers.

- Versatile and comfortable – Good for multiple articles of apparel and home decor.

Disadvantages

- Concerns – The use of so much chemicals in making the product is a question of eco friendliness.

- Durability issues – It is weak when it is wet and it’s also prone to shrinkage.

- Needs to be carefully washed to keep its form.

Viscose vs. Other Fabrics

Viscose vs. Cotton

Both cotton and viscose fabric have similar breathability levels, making them ideal for the summer months. On the flip side, cotton is much stronger when wet, unlike rayon, which becomes weak and loses its shape. While cotton is more durable and easy to maintain, viscose has a greater chance of shrinking. When it comes to softness, rayon has a more silky feel, while cotton has a coarser, more natural touch.

Viscose vs. Polyester

Due to being artificial, polyester comes out stronger, more durable and wrinkle free when compared to viscose, however it is not breathable which makes it retain heat and cause discomfort in warm climates. On the contrary, Viscose is very useful in hot temperatures as it is able to retain moisture and allow air circulation. rayon needs more care when being washed because it must be washed gently to make sure its drape and softness is preserved, while polyester can be cared for easily.

Viscose vs. Silk

Due to its silky smooth texture, rayon is often referred to as artificial silk. Like silk, viscose has some positive features too, and unlike silk, it is cheap. Viscose, however, is very friendly on the pocket in comparison to silk, but lacks in durability. While silk is self cleaning and very durable, hypoallergenic, rayon is not. rayon tears easily and needs a lot of care.

Sustainability and Environmental Impact

Although viscose/rayon is biodegradable, its production due to intensive chemicals involvement is highly polluting.

Renewable source – Constructed from wood pulp which is a natural renewable resource.

Chemical pollution concerns – Carbon disulfide used is dangerous to the workers and the surrounding environment.

Sustainable alternatives – Eco-friendly bamboo viscose with a closed loop production system is referred to as Lyocell and Tencel.

Certifications – For a more sustainable use of rayon, search for FSC and OEKO-TEX certified products.

Care and Maintenance of Viscose

- Hand Wash Only: Always hand wash viscose garments in cold water and use a mild detergent to avoid damage.

- Gentle Wash Cycle: When washing by machine, choose a delicate cycle and put the garment into a mesh laundry bag for safekeeping.

- Do Not Use Strong Cleansers: Strong soaps and bleach can damage the fibers and cause them to become discolored.

- Do Not Twist: Creating a twisting or wringing motion with rayon fabric causes stretching and loss of shape. Press out excess water with care.

- Air Drying: To dry the garment use a towel and lay it flat. Do not hang wet viscose garments as this will cause them to lose shape due to the water weight.

- Avoid Prolonged Exposure to The Sun: The sun can weaken and fade the fabric over time.

- Low Temp Iron: To get rid of scars, iron viscose when it is a bit wet using low heat. Always use the reverse side in order to protect the fibers.

- Use a Steamer: An alternative to ironing is using a steamer. It helps avoid burning and damaging the fabric.

- Handle Wisely During Storage: Viscose garments should be kept folded and not hung to avoid stretching. Put them in a cool and dry area to reduce moisture build-up.

- Don’t Wash Often: Washing the garment too frequently leads to weakened fibers, increases risk of pilling and shrinks the garment.

- Add Fabric Softener: To maintain the smooth texture and reduce friction that leads to pilling, softer fabric is needed.

- Avoid Using Water that is Too Hot: As heat causes rayon garments to shrink, it’s best to use cold or lukewarm water.

History of Viscose

Viscose’s history remarkably begins in the late nineteenth century when it was made as an inexpensive substitute to natural silk. Thus, fine fabrics became available to a larger population.

French scientist Hilaire de Chardonnet experimented with cellulose in 1883, which allowed him to produce an early type of artificial silk. Nevertheless, his method was very dangerous due to the high amounts of flamability and was not suitable to be used for industries. Later, this process was improved by Charles Frederick Cross, Edward John Bevan, and Clayton Beadle in 1892, which resulted in the invention of viscose rayon.

In the 1920s to 1930s, rayon was broadly accepted in fashion and domestic textiles, since it was low-cost and had a similar appearance to silk. This once again changed the textile world since the fabric was eligible as elegant while also being budget-friendly.

Future of Viscose

Modern advancements in technology have led to the innovation of lyocell and bamboo rayon, two alternatives that use more eco-friendly processes compared to Viscose. While Viscose poses a hazardous threat to the environment, its use in the fashion world has not diminished. It looks like there is hope for sustainable rayon with new alternatives being introduced.

Conclusion-

If you ever wanted an affordable fabric with a luxurious touch, rayon is pedal perfect, being a staple in the fashion industry. It is also used in home textiles. Even though it offers comfort, elegance, and has a silky touch, rayon does require special maintenance in order not to shrink or become damaged.

There are some environmental concerns; however, the advancements in sustainable alternatives like Tencel and bamboo viscose are creating a greener future for Viscose. For all the lovers of silk, but would prefer something more friendly for the wallet, rayon is an amazing selection. Read More>>Pima cotton, Muslin Fabric.

Would you pick Viscose for your next home decor or fashion purchase?

FAQS

Is viscose/rayon natural or synthetic?

Viscose is semi-synthetic, made from natural wood pulp through a chemical process.

Is viscose/rayon eco-friendly?

It is biodegradable but has environmental concerns due to extensive-chemical usage in its production process.

How does viscose/rayon compare to cotton?

Viscose is softer and silkier, but cotton is more durable and absorbent.

Can viscose/rayon be machine washed?

It is best to hand wash or use a gentle machine cycle to avoid shrinkage.

My spouse and I stumbled over here by a different

web page and thought I might as well chehk things out.

I like what I see so i am just following you. Look

forward to looking into your weeb page yet again.

Thank you so much for stopping by—and for the follow! I’m really glad you liked what you saw. Looking forward to having you visit again soon!

You have made some decent points there. I looked on the web for more

information about the issue and found most individuals will go along with your

views on this site.

Hi there! This is my first visit to your blog!

We are a collection of volunteers and starting a new project in a community in the same niche.

Your blog provided us valuable information to work on. You have done a marvellous job!

Great blog! Do you have any tips and hints for aspiring writers?

I’m hoping to start my own blog soon but I’m a little lost on everything.

Would you recommend starting with a free platform like WordPress or go

for a paid option? There are so many choices out there that I’m totally overwhelmed ..

Any tips? Bless you!

Thanks for your personal marvelous posting! I genuinely enjoyed reading it, you may be a great author.I will remember to bookmark your blog and

may come back from now on. I want to encourage you to definitely continue your great posts,

have a nice weekend!

Hi! I’ve been reading your website for a long time now and finally got the courage to go

ahead and give you a shout out from Kingwood Texas!

Just wanted to say keep up the fantastic work!

With havin so much written content do you ever run into any

issues of plagorism or copyright violation? My website has a lot of completely unique content I’ve either authored

myself or outsourced but it appears a lot of it is popping it up all

over the web without my agreement. Do you know

any solutions to help reduce content from being stolen? I’d really appreciate it.

It’s remarkable in support of me to have a site, which is useful in favor

of my know-how. thanks admin

Hello, I do believe your website could be having internet browser compatibility problems.

Whenever I look at your site in Safari, it looks fine but when opening in IE, it’s got some overlapping issues.

I just wanted to give you a quick heads up! Aside from that, great website!

I am really impressed with your writing skills as well as with the layout on your

weblog. Is this a paid theme or did you customize it yourself?

Either way keep up the nice quality writing, it’s rare to see a

great blog like this one nowadays.

I have been exploring for a little for any high quality articles or weblog posts in this kind of area .

Exploring in Yahoo I at last stumbled upon this website.

Studying this information So i’m satisfied to express that I

have a very good uncanny feeling I found out just

what I needed. I most no doubt will make certain to do not put out of your mind this website and give

it a look on a constant basis.

Wow, amazing blog layout! How long have you been blogging for?

you make blogging look easy. The overall look of your web site is fantastic,

let alone the content!

Incredible story there. What occurred after? Thanks!

These are actually great ideas in concerning blogging. You have touched some fastidious things here.

Any way keep up wrinting.

What’s Happening i am new to this, I stumbled upon this I have found It absolutely helpful and

it has helped me out loads. I am hoping to give a contribution &

help different users like its aided me. Good job.

I don’t even understand how I ended up right here, but I assumed this publish was great.

I do not realize who you’re however certainly you

are going to a famous blogger in the event you are not already.

Cheers!

When I originally commented I clicked the “Notify me when new comments are added” checkbox and now each time a comment is added I get three emails with the same comment.

Is there any way you can remove people from that service?

Appreciate it!

If some one desires expert view regarding blogging and site-building afterward i propose him/her to go to see this blog, Keep up the fastidious

work.

You’ve made some really good points there. I checked on the

net to learn more about the issue and found most people will go

along with your views on this web site.

Hello there! This is my 1st comment here so I

just wanted to give a quick shout out and tell you I truly enjoy reading through your articles.

Can you suggest any other blogs/websites/forums that cover

the same topics? Appreciate it!

Great article.

Attractfive section of content. I just stumbled upon your

site and in accession capital to assert that I get in fact enjoyed account

your blog posts. Any way I will be subscribing to your augment and even I

achievement you access consistently rapidly.

Your method of describing everything in this article is in fact fastidious,

every one can easily understand it, Thanks

Attractive section of content. I just stumbled upon your weblog and in accession capital to assert that I

get actually enjoyed account your blog posts. Any way I’ll be subscribing to your augment and even I achievement you access

consistently quickly.

Hi! I just want to offer you a huge thumbs up for your excellent information you’ve got right here on this post.

I am coming back to your site for more soon.

Pretty! This was an extremely wonderful post. Thank you for providing this information.

Awesome things here. I am very glad to peer your article.

Thanks so much and I am looking ahead to contact you.

Will you kindly drop me a mail?

Hello there! This post couldn’t be written any better!

Reading this post reminds me of my previous room mate! He always kept talking about this.

I will forward this article to him. Fairly certain he will have a good read.

Many thanks for sharing!

Hi there, I found your web site by way of Google at the same time as

searching for a comparable matter, your website got here up, it seems to be good.

I’ve bookmarked it in my google bookmarks.

Hi there, simply was alert to your blog through Google, and found that it is really informative.

I’m gonna be careful for brussels. I will appreciate if you continue this in future.

A lot of people can be benefited out of your writing.

Cheers!

Yes! Finally someone writes about tips kesehatan leave a comment.

Nice blog here! Also your site loads up very fast!

What host are you using? Can I get your affiliate link to your host?

I wish my web site loaded up as quickly as yours lol

My relatives always say that I am killing my time here at web, but I know

I am getting know-how daily by reading such nice posts.

I loved as much as you will receive carried out right here.

The sketch is tasteful, your authored material stylish. nonetheless, you command get got an nervousness over that you wish be delivering the following.

unwell unquestionably come more formerly again since exactly the same nearly very

often inside case you shield this hike.

Wow, incredible weblog structure! How long have you ever been running a blog for?

you made blogging look easy. The full glance of your website is magnificent, let

alone the content!

This is the missing piece of the puzzle. Incredible.

always i used to read smaller posts which as well clear their motive, and that is also happening with this

article which I am reading now.