Introduction

For centuries, satin has been seen as the epitome of elegance, luxury, and sophistication. From a beautiful evening gown to home decoration, satin’s smooth texture and shiny surface make it a favorite for many designers and fabric lovers. But what is satin? Is it a type of fabric or is it a weaving type? In this guide, we will analyze satin’s unique characteristics, explore how manufacturers produce it, and examine its various uses in fashion and other industries.

Is Satin a Fabric or a Weave?

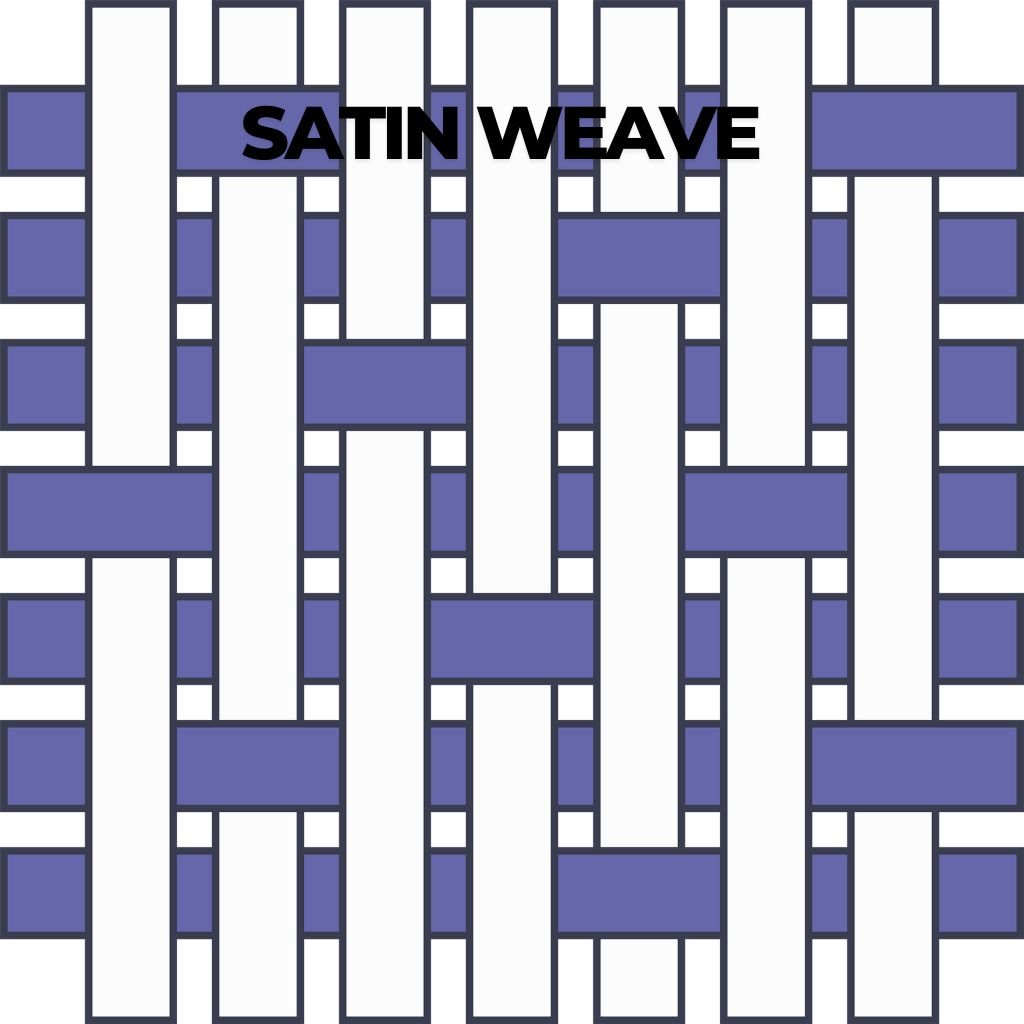

Many people have a misconception that satin refers to a particular type of material like cotton or silk. Nonetheless, satin is a type of weaving technique that creates a sleek surface which is soft and has a smooth texture. Unlike other weaves, such as the plain weave or the twill weave, satin’s structure is unusual and light is able to reflect on the fabric giving it a sheen.

The satin stitch weave is defined by long, floating threads on the warp that contain minimal interlacing. This results in a high gloss surface on one side and a dull finish on the other side. This luxurious appearance has made satin a desired fabric for centuries.

A Brief History of Satin

Satin’s origins date back a thousand years to ancient China where it was first woven from silk. History records that artisans crafted the ideal versions of satin and exported them to the Middle East and Europe through Quanzhou, a critical location on the Silk Road. During the Middle Ages, only the aristocrats had access to wearing satin due to its heavy mark of social class and wealth and thus, became a lifestyle statement.

Satin production became widespread during the Industrial Revolution due to the introduction of synthetic fibers like Polyester and Nylon. Today, manufacturers integrate satin into everyday items such as sleepwear, undergarments, and home decor, in addition to its essential role in high-fashion clothing.

Production Process of Satin

To create satin, manufacturers must first complete multiple thorough processes to achieve smoothness and lustrousness. You can find a detailed outline of this process below in the subheadings given:

1: Choosing Fiber

- Used Materials: Satin’s fibers include silk, polyester,” nylon, and acetate. Different fibers affect the texture, strength, and price of the fabric.

- Silk: Exquisite and classic but costly.

- Polyester: Cheap, strong, and commonly used.

- Nylon: Light, tough, and often used for undergarments.

- Acetate: Shiny but weak; used for linings.

- Quality Control: The fiber is checked for consistency and quality before being spun into yarn.

2. Spinning the Yarn

- Preparation: The cleaned selected fibers are carded to arrange them in a uniform direction.

- Spinning: The fibers are spun into yarn utilizing spinning machines. The spinning machines used to make the satin fabric will determine the quality and thickness of the yarn.

- Fine Yarns: These Result in smoother, shinier satin.

- Thicker Yarns: These Result in a heavier, less glossy fabric.

3. Weaving Process

- Satin Weave Technique: Satin is made with a special technique called satin weave. In this procedure, warp threads (longitudinal threads) float over a couple of weft threads (cross threads). Usually, the warp threads cover around 4 to 7 weft threads before they interlace, and this results in a gleaming side and a dull side.

- Types of Satin Weave

- Warp-Faced Satin: The threads of warp yarns are visible and dominant to the front appearance of the cloth and this gives a glossy look to the fabric.

- Weft-Faced Satin: The threads of weft yarns are dominant and visible at the front of the fabric which makes it soft and gives a silky glow to the fabric.

- Loom Setup: The yarns are placed on a loom to start the weaving process. Everything should be very accurate in order to achieve the fabric’s shine and smoothness.

4. Dyeing the Fabric

- Pre-Washing: The woven satin fabric is washed with an industrial detergent to remove any impurities or residues.

- Dyeing Step: The satin piece is dipped into the dye baths to get the desired color. It is then placed in a color bath. Fabrics with satin polish finish have a smooth and glossy surface which helps in even absorption of all colors.

- Special Effects: Decoration can also be done using specific method of coloring for example ombre or gradient patterns.

5. Finishing Treatments

- Calendaring: The process polishes the fabric by passing it through heated rollers to increase its luster and smoothness.

- Mercerization (for cotton satin): A treatment usually carried out on fabrics that increases their strength and luster as well as the affinity for dyeing.

- Anti-Static Treatment: Used on synthetic satin cloth to help eliminate static cling. Softening: Chemical softeners may be added to enhance the feel of the fabric.

6. Quality Control and Inspection

- Visual Inspection: Check for anomalies such as snags, irregular dyeing patterns, and errors in weaving in the fabric.

- Testing: Specimens are checked for durability, shrinkage, and colorfastness.

- Grading: Manufacturers grade the fabric based on its quality, specification, and purpose, such as high-end fashion use or ordinary fabric.

7. Cutting and Packaging

- Cutting: The final satin fabric is cut for distribution as rolls or bolts.

- Packaging: The fabric is packaged to avoid any damage during shipment.

Different Types of Satin Fabric

Satin comes in multiple varieties, each with unique characteristics suited for different applications:

Charmeuse Satin

- Wet, malleable, flexible and ultra lightweight.

- Often manufactured into evening gowns, blouses, and lingerie.

Crepe-Back Satin

- A two-tone glossy and lustrous texture allows the fabric to be worn in reverse.

- Best identified with formal wear and haute couture.

Duchess Satin

- Opaque, rigid, and rich in value.

- Commonly used for wedding dresses and tailored formal wear.

Antique Satin

- Matte satin with a little bit of texture.

- Commonly used for furnishings and curtains.

Slipper Satin

- This satin variety is extensively used in making accessories and footwear.

Properties of Satin: What Makes It Special?

Lustrous Sheen and Soft Texture

The visual sheen of satin gives it a luminous appeal while adding to the softness of touch.

Luxurious Drape

How satin hangs and flows over people or surfaces exudes sophistication which is ideal for classy dresses.

Durability

Satin has a sturdy nature despite its fragile looks, especially synthetic satin which is particularly resistant to wearing and tearing.

Versatility

Satin meets various needs ranging from fashion to home decor due to its wide varieties and its versatility.

Temperature Regulation

While synthetic satin retains heat, silk satin is breathable and moisture-wicking which makes it perfect for hot weather.

Popular Uses of Satin Fabric

Fashion and Apparel

- Satin Evening Gowns and Bridal Wear – Draped satin satins’ stunning silky texture and glossy finish make it one of the most preferred materials for bridal wear and formal dresses.

- Satin Lingerie And Sleepwear – The material effortlessly glides against the skin which makes it ideal for lingerie and nightwear.

- Blouses and Dresses – Satin adds an element of class and elegance to day-to-day clothing.

Home Decor

- Bedding and Pillowcases – People prefer satin sheets because they are easy to maintain and have a smooth finish.

- Curtains and Drapery – It enhances the beauty of home interiors.

- Upholstery – Used in cover fabrics and elite furniture.

Accessories and Footwear

- Satin’s luster transforms accessories such as scarves and handbags.

- Footwear – Slipper satin is a popular material for dress shoes.

Dance and Performance Costumes

- The sheen produced by satin adorns the wearer, bedecking them with glamour alongside enhancing their movement on stage.

Care Tips

- Silk Satin – Use a small amount of laundry detergent when hand washing in cold water.

- Synthetic Satin – Put in the washing machine on a gentle cycle using a mesh laundry bag.

- Lay flat to air-dry, or hang on a padded hanger to air-dry to help maintain the garment’s shape.

- Keep away from direct sunlight to avoid color loss.

- Set your iron on low heat and always cover the cloth with a barrier pad.

- Store satin garments on padded hangers or carefully fold them inside a breathable bag.

Satin vs. Similar Fabrics

| Feature | Satin | Silk | Sateen | Taffeta |

| Texture | Smooth & glossy | Soft & natural sheen | Softer, less glossy | Crisp & stiff |

| Composition | Silk, polyester, etc. | 100% silk | Cotton with a satin weave | Synthetic or silk |

| Use | Apparel, bedding | Luxury clothing | Sheets, drapes | Evening wear |

| Breathability | Varies (silk is best) | Highly breathable | Moderate | Low |

Common Myths About Satin

- Myth: Satin’s sole fabric source is silk.

Fact: Satin can also be made from silk, polyester, acetate, and Nylon. - Myth: Satin and silk mean the same thing.

Fact: Silk is a fiber and satin is a weave of a particular material, silk, or another fiber. - Myth: It is hard to take care of satin fabric.

Fact: Satin comes with many advantages such as durability, if maintained with care.

Sustainability and Eco-Friendliness

Although silk satin is compostable and environmentally friendly, synthetic satin (from polyester or nylon) can take decades to break down, all while increasing microplastic pollution. For a more eco-conscious selection, consider silk satin or recycled polyester satin.

Conclusion-

People have long regarded satin as a luxurious, versatile fabric with an incredibly rich history. The fabric offers a distinct touch of class and practicality to any occasion whether it be a special event, home decor, or enjoying comfort from satin beddings. Understanding the properties, uses, and care requirements associated with satin can help maximize its beauty and durability.

Next time, while encountering the fabric, you will be glad to have known why satin possesses such uniqueness. Its modern applications and ancient origins continue to inspire a myriad of people. From its silky texture to stunning luster, satin is not just another fabric, it’s a work of art.

FAQs

Does satin only come in silk?

No, satin can be made from silk, polyester, nylon, and acetate.

What’s the difference between satin and sateen?

Satin is made with floating warp threads, while sateen uses floating weft threads, giving it a softer sheen.

Is satin breathable?

Silk satin is highly breathable, while synthetic satin tends to trap heat.

Why is satin used for pillowcases?

Its smooth texture reduces friction, preventing hair breakage and wrinkles.

[…] What Is Satin? A Guide to Its Weave, Texture, Production, &Uses […]

[…] What Is Satin? A Guide to Its Weave, Texture, Production, &Uses […]

[…] muslin remains a preferred fabric for many. But what makes muslin stand apart from other oxfords, sateens, and cambric […]

Hey there!

Looking for something new to play?

We just launched a collection of browser-based games at DreamWeaver Studios — no downloads, just instant fun!

From casual clickers, there’s something for everyone.

Try it out now

Clear your head and game on — it’s 100% free to play.

Enjoy!

Your new favorite gaming spot

Hey there!

Looking for something fun to play?

We just launched a collection of browser-based games at DreamWeaver Studios — no downloads, just instant fun!

From brain-teasing puzzles, there’s something for everyone.

Try it out now

Unwind a little — it’s 100% free to play.

Enjoy!

Your new favorite gaming spot

Hi everybody, here every person is sharing these kinds of experience, therefore it’s nice to read this blog, and I used

to pay a quick visit this blog all the time.

Welcome for this useful information, I have bookmarked and written some things down. I will be checking back, from time to time too.

Welcome for this useful information, I have bookmarked and written some things down. I will be checking back, from time to time too.

First off I would like to say superb blog! I had a quick question that I’d like to ask if you don’t mind.

I was curious to find out how you center yourself and clear your thoughts prior to

writing. I have had difficulty clearing my mind in getting my thoughts out.

I truly do enjoy writing however it just seems like the first 10 to 15 minutes tend to be wasted simply just

trying to figure out how to begin. Any suggestions

or hints? Appreciate it!

[…] Luxurious sheen […]

[…] Satin’s sheen provides a luminous appeal, enhancing the overall glamour of the wearer. […]

[…] weave structure enhances its ability to reflect light and create movement. You notice how the horizontal weft threads ride over multiple vertical warp threads. The long interweaving threads reflect more light, producing a shiny appearance. This structure […]

Real great info can be found on weblog. “Education is what most receive, many pass on, and few possess.” by Karl Kraus.

F*ckin’ remarkable things here. I am very satisfied to see your post. Thank you so much and i am having a look ahead to contact you. Will you please drop me a mail?

I consider something really special in this web site.